Implementing robust safety protocols in repair facilities is paramount for operational success, employee welfare, and customer satisfaction. These include proper training on hazardous materials, mandatory personal protective equipment (PPE), adherence to environmental regulations, and consistent application of safety measures across collision and vehicle paint repairs. Regular staff training reduces accidents, improves efficiency, and fosters a culture of safety awareness, ultimately enhancing the facility's reputation and performance in the competitive automotive repair market.

In the dynamic landscape of repair facility operations, prioritizing safety is not just a moral imperative—it’s a strategic necessity. This article delves into essential safety measures that transcend mere compliance, focusing on enhancing operational efficiency and fostering a proactive culture. From implementing robust protocols and training programs to leveraging technology for real-time monitoring, discover how these strategies transform your repair facility into a safer, more productive environment.

- Implementing Comprehensive Safety Protocols

- – The importance of a structured safety program

- – Regular staff training and its impact on accident prevention

Implementing Comprehensive Safety Protocols

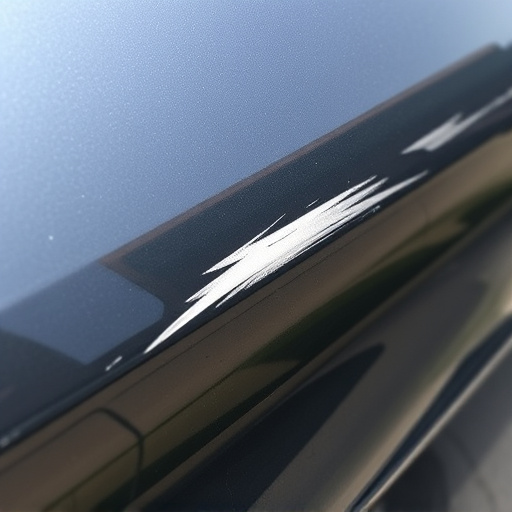

In any repair facility, implementing comprehensive safety protocols is paramount to ensuring smooth operations and maintaining a positive work environment. These protocols extend beyond basic health and safety measures, encompassing every aspect of the collision damage repair or vehicle paint repair process. By integrating robust safety measures, such as proper training for staff on handling hazardous materials, using personal protective equipment (PPE), and adhering to strict environmental regulations, facilities can minimize risks significantly.

A well-structured safety system in a collision center not only protects employees but also enhances operational efficiency. It reduces downtime caused by accidents, improves productivity by preventing injuries that might require medical attention, and ensures consistent quality in collision damage repair and vehicle paint repair services. This, in turn, leads to higher customer satisfaction, fostering a positive reputation for the facility and promoting long-term success.

– The importance of a structured safety program

In the dynamic landscape of automotive repair facilities, prioritizing safety is paramount to operational excellence. A structured safety program serves as the cornerstone for any successful auto body shop or car scratch repair center, fostering an environment conducive to efficiency and productivity. By implementing comprehensive safety measures, these facilities can mitigate risks, prevent accidents, and ensure the well-being of their workforce—all essential components for achieving top-tier performance.

A robust safety program encompasses various strategies tailored to the unique challenges of the repair facility. This includes regular training sessions for employees on safety protocols, proper use of equipment, and handling hazardous materials. Additionally, maintaining a clean and organized workspace, enforcing strict adherence to safety gear policies, and having clear emergency response plans contribute significantly to enhancing operational efficiency in car body restoration processes.

– Regular staff training and its impact on accident prevention

Regular staff training is a cornerstone of any successful repair facility’s safety measures. By investing in comprehensive and ongoing education for their workforce, facilities can significantly reduce the risk of accidents and improve operational efficiency. Trained employees are better equipped to handle complex tasks, such as car body repair or auto glass replacement, with precision and speed. They also possess a deeper understanding of safety protocols, ensuring they follow best practices consistently, which is vital in high-pressure environments like repair shops where mistakes can lead to severe consequences.

This proactive approach extends beyond individual skill development. Regular training sessions foster a culture of safety awareness across the entire facility. Employees become more attuned to potential hazards, from slip-and-fall risks to the safe handling of hazardous materials used in hail damage repair. Such a culture not only prevents accidents but also enhances overall productivity by streamlining processes and minimizing downtime caused by safety incidents, ultimately contributing to a safer and more efficient repair facility.

By implementing robust repair facility safety measures, such as comprehensive protocols and regular staff training, operations can run smoothly and efficiently. These proactive steps not only mitigate risks but also foster a culture of accident prevention, ultimately enhancing the overall productivity and reputation of the facility. Prioritizing safety is key to ensuring a vibrant and prosperous future for any repair operation.