Prioritizing repair facility safety is a multi-faceted approach integral to automotive maintenance compliance and best practices. This involves meeting stringent standards for physical environments, processes, and equipment, addressing hazards like hazardous materials and electrical risks. Specialized services require unique considerations, such as enhanced ventilation. Top facilities embrace continuous improvement through regular staff training, advanced tools, high-quality materials, and efficient waste management, prioritizing employee safety and setting industry benchmarks.

In the dynamic landscape of automotive repair, ensuring repair facility safety is not just a best practice—it’s a regulatory imperative. This article delves into the intricate relationship between repair facility safety and industry compliance standards, exploring key areas such as understanding safety requirements, effectively implementing compliance, fostering continuous improvement, and adopting robust risk mitigation strategies. By aligning with these standards, repair facilities can enhance operational efficiency while maintaining the highest safety benchmarks.

- Understanding Repair Facility Safety Requirements

- Implementing Compliance Standards Effectively

- Continuous Improvement and Risk Mitigation Strategies

Understanding Repair Facility Safety Requirements

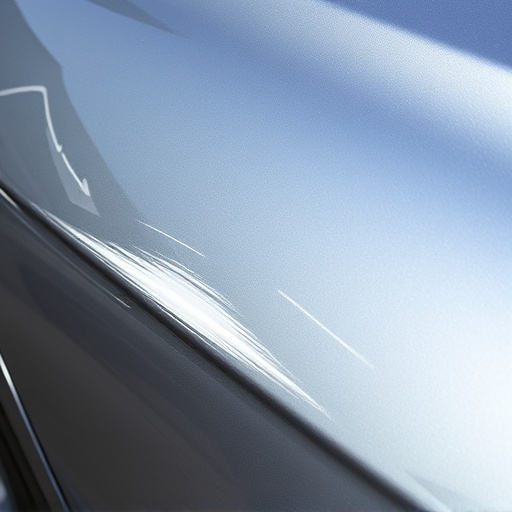

In the realm of automotive maintenance and repair, ensuring safety within repair facilities is paramount, serving as a cornerstone for adhering to industry compliance standards. This involves a multifaceted approach that encompasses not just physical surroundings but also processes and equipment used in various types of repair shops, be it an auto repair shop, auto body shop, or one specialized in car scratch repairs.

Safety requirements manifest through stringent regulations set by governing bodies, aiming to safeguard employees, customers, and the environment from potential hazards. For instance, proper handling and disposal of hazardous materials, adherence to electrical safety standards, and implementation of robust emergency response protocols are integral parts of maintaining a safe repair facility. Moreover, specific considerations come into play depending on the services offered; for a car scratch repair shop, focusing on minimizing dust and ensuring proper ventilation is crucial to both employee health and the quality of repairs.

Implementing Compliance Standards Effectively

Implementing effective compliance standards is pivotal for any repair facility, be it a modern automotive body shop or a classic car restoration center. This involves integrating safety protocols into day-to-day operations to meet industry benchmarks. By doing so, facilities ensure not only adherence to legal requirements but also create a safer environment for employees and vehicles under their care.

For an automotive body shop or car bodywork specialist, compliance standards serve as a roadmap for managing hazardous materials, implementing proper waste disposal methods, and ensuring the use of protective gear. These measures are essential in preventing accidents, minimizing environmental impact, and maintaining the high-quality standards expected in the industry.

Continuous Improvement and Risk Mitigation Strategies

In the ever-evolving landscape of repair facility safety, continuous improvement is not just a goal but a necessity. Top-tier facilities understand that risk mitigation strategies are integral to their operational success and compliance with industry standards. By adopting a proactive approach, they seamlessly integrate safety measures into every stage of the repair process, from initial assessment to final quality check. This involves regular training for staff on the latest safety protocols, ensuring adherence to regulations specific to auto repair shops, collision damage repair centers, and fender repair facilities.

Innovative risk management techniques play a pivotal role in this strategy. These include implementing advanced diagnostic tools to minimize errors during complex repairs, utilizing high-quality materials that comply with industry standards, and adopting efficient waste management practices to reduce environmental hazards. Such strategies not only safeguard the well-being of employees but also ensure the facilities maintain their reputation as leaders in repair facility safety, setting benchmarks for others in the industry.

Repair facility safety is not just a best practice—it’s an industry compliance standard. By understanding the specific requirements, effectively implementing relevant standards, and adopting continuous improvement strategies, repair facilities can mitigate risks, ensure regulatory adherence, and create a safer environment for employees and customers alike. These measures are essential to maintaining a competitive edge in today’s market, where safety and quality go hand in hand.