Safety Systems Verification Reports (SSVRs) are essential for collision repair safety, guiding manufacturers and centers to verify critical systems like airbags and brakes against industry standards. Comprehensive documentation is key, meticulously recording vehicle states before and after collision, enabling accurate restoration and promoting transparency. Structured, detailed documents with clear formatting and version control enhance accessibility and verification processes, ensuring compliance with safety standards and regulations.

In the realm of safety systems verification, comprehensive documentation is paramount. This article delves into the critical role of documentation within safety systems verification reports, elucidating its importance in maintaining accuracy and fostering trust. We explore best practices for creating robust, detailed records that not only navigate complex processes but also serve as a testament to the integrity of safety system evaluations. Understanding these components is essential to ensuring effective and reliable safety systems verification.

- Understanding Safety Systems Verification Reports

- The Role of Documentation in Ensuring Accuracy and Trustworthiness

- Best Practices for Creating Comprehensive Documentation

Understanding Safety Systems Verification Reports

Safety Systems Verification Reports (SSVRs) are crucial documents that outline the meticulous process of ensuring a vehicle’s safety features function optimally. These reports serve as a bridge between the manufacturer and repair centers, especially collision repair centers, guaranteeing that critical safety systems meet stringent industry standards. Each SSVR meticulously documents tests performed, outcomes achieved, and any deviations or adjustments made during the verification process.

Comprehending these reports is vital for vehicle restoration specialists. It enables them to verify the integrity of airbag deployment mechanisms, brake systems, and other active safety features, ensuring that a repaired vehicle maintains its original safety specifications. By adhering to SSVR guidelines, collision repair centers can deliver high-quality work, instill customer confidence, and contribute to road safety across the industry.

The Role of Documentation in Ensuring Accuracy and Trustworthiness

Documentation plays a pivotal role in the safety systems verification process, acting as a cornerstone for ensuring accuracy and instauring trustworthiness across all stages of automotive collision repair. Thorough and precise records are essential to capture every detail of a car’s pre-and post-collision states, encompassing structural integrity, functional components, and safety features. This meticulous documentation serves as a reliable reference point, enabling expert technicians to make informed decisions during the restoration process.

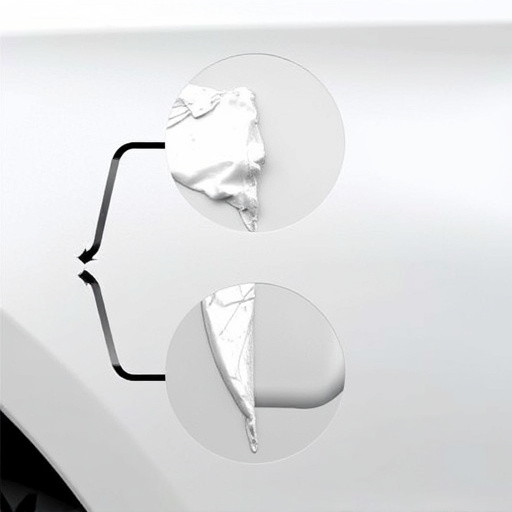

In the context of safety systems verification reports for collision repair shops, comprehensive documentation facilitates a clear understanding of the vehicle’s original design, any pre-existing damage, and the extent of the collision impact. It allows for the accurate identification of parts that require replacement or repair, ensuring that every safety system—from airbags to brake mechanisms—is meticulously assessed and restored to its optimal functioning state. This rigorous documentation process not only guarantees the highest standards of quality control but also fosters transparency and accountability throughout the entire automotive collision repair process.

Best Practices for Creating Comprehensive Documentation

Comprehensive documentation is a cornerstone of effective safety systems verification reports. It ensures that every aspect of the system’s design, implementation, testing, and validation is meticulously recorded, providing a clear trail of evidence for future reference. Best practices involve creating structured documents with clear headings, bullet points, and tables to enhance readability. Using consistent formatting and version control, such as through document management systems, allows for easy updates and access by authorized personnel across various departments, including auto repair services and car damage repair centers that incorporate safety systems in their operations.

Additionally, documentation should be detailed enough to enable independent verification and validation (IV&V) processes. It must include specifications, test plans, results, and any deviations or exceptions encountered during testing. Integrating this information into the report ensures that auto dent repair processes are aligned with safety standards and regulations, fostering a culture of transparency and accountability in the automotive industry.

Documentation plays a pivotal role in the integrity of safety systems verification reports, ensuring that critical information is accurately recorded, accessible, and reliable. By adhering to best practices for comprehensive documentation, organizations can enhance the trustworthiness of their safety systems verification processes, fostering a culture of transparency and accountability. Effective documentation not only facilitates efficient navigation and understanding of complex systems but also serves as a robust reference point for future audits, updates, and improvements, ultimately reinforcing the reliability of safety protocols.