The Mercedes Rollover Protection System (MRPS) is a life-saving feature that detects unstable driving conditions and activates safety features to prevent rollovers. Its effectiveness relies on precise torque-specific installations and proper bodywork repairs, ensuring structural integrity. Auto collision repair specialists, equipped with advanced tools and expertise, perform these crucial installations and repairs, enhancing passenger safety during rollover accidents.

Mercedes’ Rollover Protection System (MRPS) is a sophisticated safety feature designed to enhance vehicle stability and reduce the risk of rollovers. Understanding the intricacies of its torque-specific installations is crucial for effective integration. This article delves into the MRPS, highlighting why torque-specific considerations are vital for optimal performance. We explore common challenges faced during installation and offer practical solutions, ensuring proper setup for enhanced driver safety.

- Understanding Mercedes Rollover Protection System (MRPS)

- The Importance of Torque-Specific Installations for MRPS

- Common Challenges and Solutions in Installing MRPS

Understanding Mercedes Rollover Protection System (MRPS)

The Mercedes Rollover Protection System (MRPS) is a sophisticated safety feature designed to minimize the risk of rollovers and protect occupants during such events. This advanced system utilizes a network of sensors, actuators, and crash data recording devices to detect and respond to unstable driving conditions. When MRPS detects an imminent rollover, it promptly triggers specific safety mechanisms, such as deploying airbags and rigid energy-absorbing structures within the vehicle’s frame. These structural changes help prevent or mitigate the severe consequences of a rollover accident, enhancing passenger survival rates significantly.

Understanding MRPS involves grasping its components and how they work together. Key elements include side-impact sensors that monitor changes in vehicle dynamics and a control module that analyzes data to decide when to activate safety features. The system’s torque-specific installations are crucial for ensuring the effectiveness of these protections, as they account for the complex forces involved in rollovers. Properly managing these forces through tailored bodywork repairs, such as those offered during car collision repair services, is essential for maintaining MRPS functionality and overall vehicle safety.

The Importance of Torque-Specific Installations for MRPS

The Mercedes Rollover Protection System (MRPS) is a sophisticated safety feature designed to enhance passenger security in the event of a roll-over accident. Its effectiveness heavily relies on precise and torque-specific installations, which are crucial for ensuring optimal performance. Each component of the MRPS must be meticulously aligned and secured to withstand extreme forces during a rollover, preventing severe injuries or fatalities.

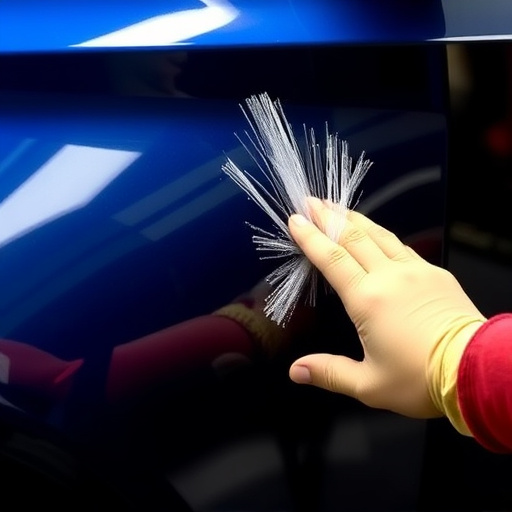

Torque-specific installations play a pivotal role in maintaining the system’s integrity. These specialized fittings ensure that the MRPS acts uniformly across various vehicle models and configurations. Car body shops equipped with expert mechanics and advanced tools can perform these crucial installations, guaranteeing that every Mercedes benz repair is done right, down to the smallest torque specifications. Proper vehicle paint repair, when combined with meticulous torque management, further bolsters the overall structural integrity of the MRPS, ultimately saving lives.

Common Challenges and Solutions in Installing MRPS

Installing the Mercedes Rollover Protection System (MRPS) presents several challenges for auto collision repair specialists. One of the primary hurdles is ensuring torque-specific installations, as misalignment can compromise the system’s effectiveness. This requires precise measurements and a deep understanding of the vehicle’s structural integrity. Auto body restoration experts must carefully study the MRPS design and factory specifications to achieve the perfect fit.

Solutions often involve advanced tools and techniques for accurate mounting. Dent removal professionals play a crucial role in preparing the car’s chassis, ensuring no existing damage impedes the proper placement of the MRPS components. By combining these specialized skills, auto collision repair technicians can overcome challenges, guarantee the system’s optimal performance, and enhance passenger safety in the event of a rollover accident.

The Mercedes Rollover Protection System (MRPS) is a vital safety feature designed to mitigate the risk of rollovers, but its effectiveness hinges on proper torque-specific installations. By understanding the unique requirements and challenges associated with MRPS installation, automotive professionals can ensure optimal performance and passenger safety. This article has highlighted the importance of precise torque control during setup, common pitfalls to avoid, and effective solutions for successful MRPS implementation, underscoring the key role it plays in Mercedes vehicles’ overall protection.