Sectioning procedures are vital in vehicle body repair, enabling shops to efficiently address extensive damage by dividing affected areas into manageable sections. This process maintains structural integrity and aesthetic accuracy through precise repairs, ultimately delivering high-quality results that meet customer expectations. Recognizing the need for sectioning is crucial, especially for complex cases like significant denting or previous repair signs, ensuring both restoration and soundness after major accidents or corrosion. Strategic layout in shops enhances productivity, quality control, and workflow efficiency, mirroring its importance across diverse industries.

Understanding sectioning procedures is essential for creating functional and aesthetically pleasing spaces. This step-by-step guide explores the art of dividing areas, offering a comprehensive approach from recognition of the need to long-term maintenance.

Learn how to identify when sectioning is crucial, explore diverse space configurations, define functionality, and select suitable materials. We’ll then walk you through a practical implementation process, ensuring your sections are not just effective but also maintainable over time. Master these procedures and unlock the potential of any space.

- Identifying the Need for Sectioning

- – Recognizing when sectioning is necessary

- – Understanding different types of spaces created by sectioning

Identifying the Need for Sectioning

In the realm of vehicle body repair, the need for sectioning procedures arises when a car or vehicle undergoes significant damage that requires precise and specialized restoration. Whether it’s due to an accident, vandalism, or manufacturing defects, sectioning becomes an essential step in the auto repair process, particularly in reputable auto repair shops. This technique involves breaking down the damaged area into manageable sections to facilitate efficient repairs, ensuring structural integrity and aesthetic precision.

Identifying the need for sectioning is crucial in determining the extent of the vehicle body repair. For instance, a car with extensive damage to its panel may require sectioning to separate the affected area from the rest of the vehicle. This approach allows auto repair technicians to work on specific sections independently, which can streamline the overall repair process and enhance the quality of the final car scratch repair. By employing these detailed sectioning procedures, auto repair shops can deliver top-notch results while ensuring customer satisfaction.

– Recognizing when sectioning is necessary

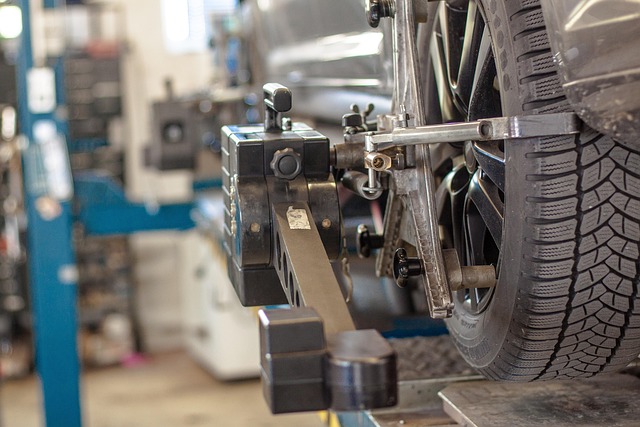

Recognizing when sectioning is necessary is a critical first step in any vehicle repair process. Sectioning procedures are essential for auto body shops to efficiently address damage, especially in complex repairs. Consider factors like extent of the damage, presence of hidden issues beneath the surface, and the need for precise measurements and material replacement when deciding if sectioning is required. For instance, an auto body shop might recommend sectioning if a vehicle’s panel has suffered significant denting, cracking, or if there are signs of previous repairs that could compromise structural integrity.

This process involves carefully cutting out damaged sections of a vehicle’s body, allowing for the removal of affected components and the installation of new, expertly fabricated parts. While it might seem like an extreme measure compared to simpler auto body services like painting or detailing, sectioning is often necessary for comprehensive and long-lasting vehicle repair, ensuring that both aesthetics and structural soundness are restored, particularly after major accidents or extensive corrosion.

– Understanding different types of spaces created by sectioning

When it comes to understanding sectioning procedures, one of the key aspects is comprehending the diverse spaces that these processes create. Sectioning isn’t merely about dividing a surface; it involves crafting distinct areas tailored for specific purposes. These sections can range from small compartments within a car body repair shop, designed for efficient tire services and precise collision repair, to larger, specialized workspaces in manufacturing settings. Each space is engineered to accommodate unique tasks, ensuring optimal productivity and quality control.

In the context of a collision repair shop, for instance, sectioning might divide the facility into dedicated areas for body work, painting, and final inspection. This strategic layout streamlines the repair process, enabling technicians to focus on their specialized tasks without interference. Similarly, in automotive assembly lines, sectioning procedures are used to create stations for various operations, from welding to quality assurance, facilitating a smooth and organized production flow. By recognizing and leveraging these spatial divisions, businesses can enhance workflow efficiency, safety, and overall operational effectiveness.

Sectioning procedures are a meticulous yet powerful tool in creating functional and aesthetically pleasing spaces. By understanding when and how to employ these techniques, whether for dividing large areas or defining smaller compartments within a room, you can enhance the overall design and usability of any space. This step-by-step guide offers a comprehensive overview, ensuring that both professionals and enthusiasts alike can master sectioning procedures effectively.