Hydraulic frame machines, crucial in automotive repair, leverage hydraulic systems to exert precise, powerful forces for tasks like metal fabrication and fender repairs. Understanding their operation, centered around fluid pressure conversion to mechanical motion, is key for technicians. Anchoring points, strategically placed across industries from auto body to car paint, secure components, guide movements, enhance stability, and ensure consistent, reliable results. Optimal anchoring point placement improves precision and efficiency in tasks like frame straightening and panel replacement, underscoring its importance for delivering high-quality automotive services.

Hydraulic frame machines are versatile tools integral to various industries, offering precision and power in a compact form. This article delves into the nuanced world of these machines, focusing on a critical component: anchoring points. Anchoring points serve as pivotal connections, enabling stable and controlled movement. By understanding their definition and significance, operators can optimize performance through strategic placement, enhancing efficiency and safety in hydraulic frame machine operation.

- Understanding Hydraulic Frame Machines and Their Basic Functionality

- The Concept of Anchoring Points: Definition and Significance

- Optimizing Performance through Strategic Anchoring Point Placement

Understanding Hydraulic Frame Machines and Their Basic Functionality

Hydraulic frame machines are sophisticated pieces of equipment designed to perform precise and powerful operations in various industries, including automotive and vehicle repair services. These machines utilize hydraulic systems to generate and control forces, enabling tasks that require significant strength and accuracy. The basic functionality involves the manipulation of a frame or structure through a series of hydraulic actuators and pumps. This technology is instrumental in processes such as metal fabrication, fender repair, and auto maintenance, where robust and consistent force application is essential.

Understanding how these machines operate is crucial for technicians engaging in vehicle repair services. The core principle revolves around the conversion of hydraulic fluid pressure into mechanical motion, allowing for the manipulation of heavy components with ease. By controlling the flow and pressure of hydraulic fluids, operators can achieve a wide range of movements, making them versatile tools for various auto maintenance tasks. This technology has revolutionized industries by enhancing efficiency and precision in processes that were once labor-intensive.

The Concept of Anchoring Points: Definition and Significance

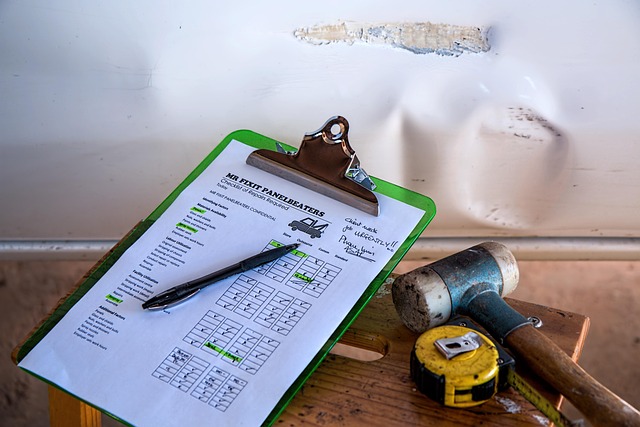

In the context of a hydraulic frame machine—a versatile tool used across various industries from auto body services to tire services and car paint services—anchoring points serve as foundational elements that secure and guide the movement of components during operation. These strategic locations act as references, enabling precise adjustments and control over the machine’s functions. By providing stability and alignment, anchoring points ensure consistent and reliable results in frame straightening and other critical tasks.

The significance of anchoring points lies not only in their structural role but also in enhancing safety and operational efficiency. Properly designed and maintained anchoring points facilitate smoother operations by minimizing vibrations and misalignments, which can lead to costly errors or even machine damage. Understanding the concept and importance of these points is crucial for operators aiming to maximize the performance and longevity of their hydraulic frame machines.

Optimizing Performance through Strategic Anchoring Point Placement

Optimizing performance in a hydraulic frame machine begins with strategic anchoring point placement. By carefully positioning these crucial components, technicians can enhance precision and efficiency during various automotive tasks such as car repair services or auto detailing. Each anchoring point serves as a stable reference, enabling operators to accurately manipulate metal structures without compromising alignment. This, in turn, ensures the integrity of auto dent repair processes, making it an essential consideration for achieving seamless outcomes.

Strategic placement allows for versatile manipulation, catering to diverse vehicle needs. Well-placed anchors facilitate complex adjustments, from frame straightening to panel replacement, thereby streamlining workflow and reducing overall service time. In the context of a hydraulic frame machine, this precision is vital for maintaining the structural integrity of vehicles, making it an indispensable aspect in delivering high-quality car repair services and auto detailing solutions.

Hydraulic frame machines, with their versatile functionality, rely heavily on anchoring points for precise control and optimal performance. By strategically placing these crucial components, operators can enhance efficiency and accuracy in various applications. Understanding the role of anchoring points is essential for maximizing the potential of hydraulic frame machines, ensuring they become indispensable tools in modern industry.