Factory seam duplication is a cutting-edge technique enhancing modern vehicle collision repair by precisely duplicating high-strength steel components' structural integrity and safety features. This specialized process involves meticulous material selection, skilled preparation, advanced machinery (including robotic welders), and stringent quality inspections to recreate intricate seams with flawless fit and strength. Offering unparalleled accuracy, faster repairs, and long-lasting results, factory seam duplication is versatile for accident repair and vintage vehicle restoration, revolutionizing auto bodywork with superior quality and efficiency.

In the realm of high-strength steel repairs, Factory Seam Duplication stands as a game-changer. This advanced technique mirrors the precision and quality of original manufacturing processes, ensuring robust and reliable structural integrity. By understanding and mastering factory seam duplication, professionals can navigate complex repairs with confidence. From material selection to precise replication, this article delves into the process, benefits, and diverse applications that make factory seam duplication an indispensable tool in modern steel fabrication.

- Understanding Factory Seam Duplication for Steel Repairs

- The Process: From Material to Perfect Replication

- Benefits and Applications of Advanced Seam Duplication Techniques

Understanding Factory Seam Duplication for Steel Repairs

Factory seam duplication is a specialized technique used to restore high-strength steel components to their original integrity after repairs or damage. This process involves creating a precise copy of an existing seam, ensuring that the replicated joint matches the strength and structural properties of the original. By utilizing advanced technologies and expert craftsmanship, auto collision centers and car bodywork services can effectively perform factory seam duplication for vehicle collision repair, guaranteeing both safety and structural soundness.

This innovative approach is particularly crucial in repairing complex steel structures found in modern vehicles. Whether it’s a faulty joint due to an accident or the need to replace worn-out parts, factory seam duplication ensures that the repair mimics the original manufacturing quality. This is essential for maintaining the vehicle’s overall performance and structural integrity, providing peace of mind for drivers who rely on their cars’ safety and reliability.

The Process: From Material to Perfect Replication

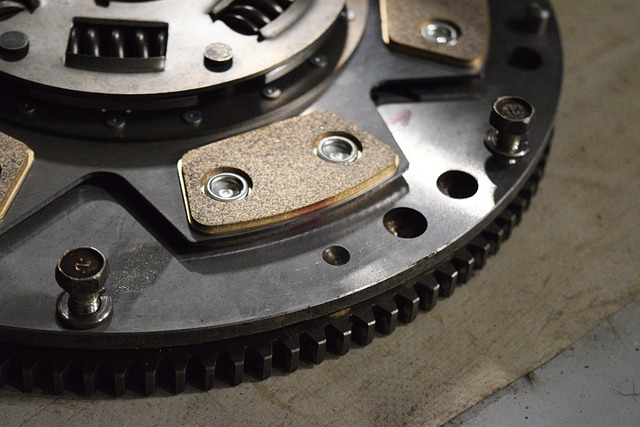

The process of factory seam duplication for high-strength steel repairs involves a meticulous journey from raw material to flawless replication. It begins with selecting the appropriate grade of steel, ensuring it matches the original specifications precisely. Skilled technicians then prepare the surface, cleaning and deburring it to create an ideal foundation for the duplicate seam.

Using advanced machinery, including robotic welders and specialized tooling, the factory seamlessly (pun intended) recreates the intricate pattern of the original seam. This technology allows for precise measurements and exact duplication, guaranteeing a perfect fit and structural integrity. The finished replicate is then thoroughly inspected to meet stringent quality standards, ensuring it’s ready to be integrated into car repair services or automotive collision repair processes, restoring vehicles to their pre-accident condition with enhanced strength and durability.

Benefits and Applications of Advanced Seam Duplication Techniques

Advanced seam duplication techniques offer a multitude of benefits for high-strength steel repairs, enhancing both the quality and efficiency of auto body work. These cutting-edge methods mimic the precision of factory production lines, ensuring seamless integration and superior structural integrity in collision centers. By employing specialized equipment and software, technicians can accurately replicate complex vehicle panel shapes, ensuring that every detail aligns perfectly with the original car bodywork design.

The applications of these advanced techniques are vast within the realm of auto maintenance. From repairing damage caused by accidents to restoring vintage vehicles, factory seam duplication provides an unparalleled level of accuracy. This technology not only expedites the repair process but also guarantees long-lasting results, ensuring that fixed panels withstand rigorous tests and maintain their structural strength.

Factory seam duplication is transforming high-strength steel repairs, offering precise and robust solutions. By leveraging advanced techniques, this method ensures structural integrity and aesthetic harmony in a wide range of applications. Embracing factory seam duplication not only enhances the durability of repairs but also opens doors to innovative possibilities in manufacturing and construction.