Tesla Structural Integrity Repair is a specialized process that preserves the safety and structural integrity of Tesla vehicles after accidents, using advanced techniques and high-quality materials like steel, aluminum alloys, and composites. This meticulous approach involves reinforcing critical components such as frames, chassis, and body panels with metal braces, adhesives, or composite materials to enhance load-bearing capacity and torsional rigidity. Best practices include compatible materials, proper preparation, industry-standard bonding, CAD software for precise measurements, robotic welding systems, and automated painting processes. The result is a Tesla vehicle that maintains its original precision design and stringent safety standards, ensuring optimal structural integrity and enhanced safety upon departure from the collision center.

“In the realm of automotive engineering, Tesla stands out for its innovative designs and advanced technology. When addressing vehicle structural integrity repairs, understanding the nuances of Tesla’s process is crucial. This article explores the vital aspect of structural reinforcement during Tesla structural integrity repair. From the basics of this intricate procedure to best practices and cutting-edge technologies, we delve into ensuring the safety and strength of Tesla vehicles post-repair.”

- Understanding Tesla Structural Integrity Repair: The Basics

- The Role of Structural Reinforcement in Repair Process

- Best Practices and Technologies for Effective Reinforcement

Understanding Tesla Structural Integrity Repair: The Basics

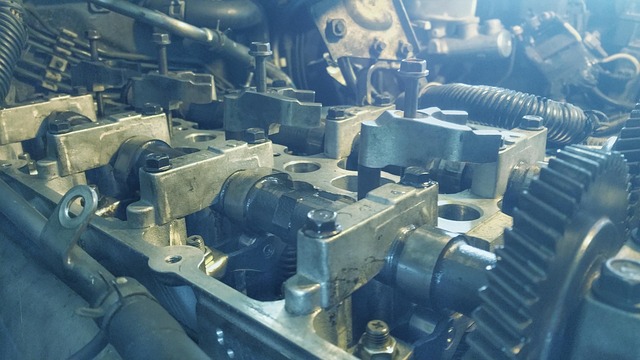

Tesla Structural Integrity Repair is a specialized process designed to ensure the safety and structural soundness of Tesla vehicles after an accident or damage. It involves meticulous evaluation and reinforcement of critical components, including the vehicle’s frame, chassis, and body panels. This repair method goes beyond conventional auto body work, focusing on maintaining the original integrity and precision-engineered design that defines Tesla cars.

The process begins with a thorough inspection to identify any structural damage or misalignments. Skilled technicians then employ advanced techniques and high-quality materials for auto frame repair and reinforcement. This may include realigning panels, replacing damaged parts, and adding structural supports to ensure the vehicle meets Tesla’s rigorous safety standards. An auto collision center equipped with state-of-the-art equipment is often the ideal setting for this intricate work, where experienced mechanics can handle complex repairs, ensuring the vehicle not only looks good as new but also performs safely on the road.

The Role of Structural Reinforcement in Repair Process

Structural reinforcement plays a pivotal role in the Tesla structural integrity repair process. It’s not just about fixing visible damages; it’s about ensuring the vehicle maintains its original strength and safety standards. During repairs, especially after incidents like fender repairs or collision center treatments, reinforcement techniques are employed to bolster weak spots. This is crucial for preserving the overall structural integrity of the vehicle body shop work.

Reinforcement methods vary depending on the extent of damage and affected areas. It could involve adding extra metal braces, utilizing high-strength adhesives, or integrating advanced composite materials. The goal is to enhance the load-bearing capacity and torsional rigidity, making the Tesla as sturdy as new. This meticulous approach guarantees that once a vehicle leaves the collision center, it’s not just repaired but structurally reinforced for enhanced safety and longevity.

Best Practices and Technologies for Effective Reinforcement

When conducting Tesla structural integrity repairs, effective reinforcement is key to ensuring both safety and longevity of the vehicle. Best practices involve utilizing high-quality materials compatible with the car’s original components. Steel, aluminum alloys, and advanced composite materials are often used for reinforcement due to their strength-to-weight ratios. These materials must be properly prepared and bonded to existing structures using industry-standard adhesives and sealants.

Technological advancements have significantly improved structural reinforcement in auto body repair, particularly in the case of Tesla vehicles known for their innovative design. Computer-aided design (CAD) software enables precise measurement and planning, while robotic welding systems offer greater accuracy and consistency. Automated painting processes ensure a seamless finish that not only enhances aesthetics but also provides additional protection against corrosion. Incorporating these best practices and technologies into the repair process directly contributes to the overall quality of Tesla structural integrity repairs, ensuring vehicles return to their optimal condition.

In conclusion, Tesla structural integrity repair is a complex yet crucial process that demands meticulous attention to detail. By understanding the basics and incorporating best practices like effective structural reinforcement using advanced technologies, professionals can ensure the safety and longevity of these vehicles. This approach not only maintains the structural integrity of Teslas but also enhances their overall performance and value in the marketplace. When done right, Tesla structural integrity repair serves as a testament to the vehicle’s innovative design and sets a high standard for automotive craftsmanship.