Mercedes spot weld bonding is a key process in high-quality automotive manufacturing, precisely fusing metal parts for enhanced structural integrity and durability. Adhering to strict standards, this technique simplifies maintenance and repairs while preserving vehicle performance and aesthetic appeal over time. It plays a crucial role in body restoration, ensuring vehicles like Mercedes maintain their original strength and safety features. This advanced method extends lifespans, enhances passenger security, and contributes to cleaner designs, transforming the automotive industry with its seamless fusion and reduced repair needs.

Mercedes spot weld bonding is a critical process that underpins the quality, longevity, and reliability of their vehicles. This precision technique fuses metal panels together, creating a robust structure essential for safety and performance. By examining the fundamentals of Mercedes spot weld bonding, we uncover how it fortifies automotive construction. Understanding its role in enhancing vehicle durability reveals its significant impact on modern design and overall driving experience.

- Understanding Mercedes Spot Weld Bonding: The Foundation of Quality Manufacturing

- How Spot Weld Bonding Enhances Vehicle Longevity and Reliability

- Unlocking the Benefits: The Impact on Modern Automotive Design and Performance

Understanding Mercedes Spot Weld Bonding: The Foundation of Quality Manufacturing

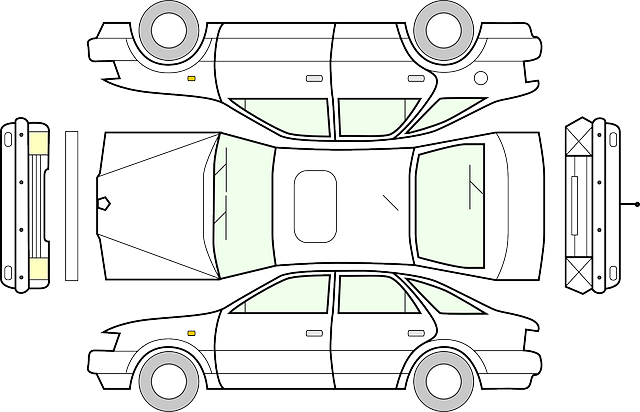

Mercedes spot weld bonding is a critical process that forms the bedrock of quality manufacturing in the automotive industry, particularly for Mercedes vehicles renowned for their longevity and reliability. This advanced technique involves precisely placing localized welds to fuse two or more metal parts together, creating a robust bond that enhances structural integrity. By employing highly specialized equipment and adhering to stringent standards, Mercedes ensures each spot weld meets exacting specifications, resulting in superior strength and durability.

This meticulous approach is pivotal in preventing issues like rust and corrosion, which can compromise the vehicle’s structural stability over time. Moreover, it plays a significant role in simplifying subsequent maintenance and repair processes, such as dent removal or tire services, by minimizing the impact of damage on the overall structure. The use of Mercedes spot weld bonding across various auto body services thus contributes to maintaining the vehicle’s optimal performance and aesthetic appeal for years to come.

How Spot Weld Bonding Enhances Vehicle Longevity and Reliability

Mercedes spot weld bonding is a pivotal process that significantly contributes to the longevity and reliability of vehicles. This advanced technique involves precisely joining two or more metal panels together, creating a robust and durable structure. By utilizing specialized equipment and precise parameters, spot welds create a strong bond that can withstand extreme forces, ensuring structural integrity over time.

In the realm of automotive repair, particularly in auto body restoration, Mercedes spot weld bonding plays a crucial role in repairing fender damage or reassembling vehicle components. The meticulous process guarantees that the restored vehicle retains its original strength and reliability, matching the manufacturer’s standards. This not only extends the lifespan of the vehicle but also enhances overall passenger safety by maintaining structural stability, which is vital for Mercedes vehicles known for their prestige and performance.

Unlocking the Benefits: The Impact on Modern Automotive Design and Performance

Mercedes spot weld bonding is revolutionizing modern automotive design and performance. By enhancing structural integrity, this advanced technique ensures vehicles withstand rigorous testing and daily wear and tear with ease. This method, unique to Mercedes, goes beyond traditional welding, offering a seamless fusion that increases longevity and reliability.

The impact extends to various aspects of automotive repair and aesthetics. Unlike conventional methods, spot weld bonding minimizes the need for extensive metalwork during repairs, preserving the original vehicle structure. Moreover, it facilitates cleaner lines and improved paint finish, evident in Mercedes’ sleek and sophisticated designs. This not only boosts the overall aesthetic appeal but also simplifies auto painting processes, ensuring a more seamless and long-lasting vehicle paint repair.

Mercedes spot weld bonding is an essential manufacturing technique that significantly contributes to vehicle longevity and reliability. By understanding and leveraging this process, automotive manufacturers like Mercedes can ensure their vehicles withstand the tests of time and performance. The benefits extend to modern design and performance, where lightweight materials and precise construction are paramount. This advanced welding method is a game-changer in the industry, fostering innovation and setting new standards for vehicle quality.