Advanced technologies like laser scanners and 3D imaging systems are transforming auto body shops, offering structural repair precision never seen before. These innovations provide accurate measurements and digital blueprints for meticulous repairs, enhancing quality, efficiency, and consistency across diverse vehicle models. By leveraging these cutting-edge tools, shops can deliver superior service from minor dent repairs to major collision damage, meeting or exceeding industry standards.

Shops employing advanced technology, comprehensive staff training, and standardized protocols achieve unparalleled accuracy in structural repairs, setting new standards in the industry. Integration of laser scanners, 3D modeling software, and digital measuring tools ensures precise measurements, enabling tailored solutions for complex structural issues. Well-trained personnel, equipped with continuous education and industry certifications, deliver consistent quality. Standardized procedures and quality control checks at every stage guarantee that each repair meets exacting precision requirements, ensuring customer satisfaction and structural integrity.

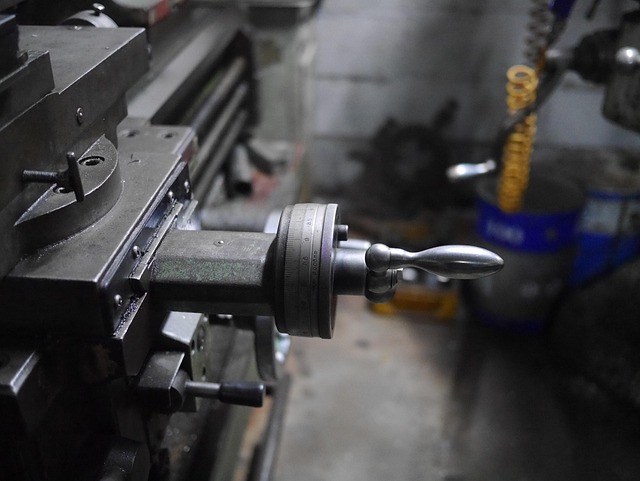

- Advanced Technology Integration for Accurate Measurements

- – Discussion on the use of modern tools and equipment for precise structural assessments.

- – Examples of laser scanners, 3D modeling software, and digital measuring tools.

Advanced Technology Integration for Accurate Measurements

In today’s digital era, advanced technology plays a pivotal role in ensuring structural repair precision across all jobs in automotive body shops. Tools like laser scanners and 3D imaging systems have revolutionized auto dent repair and automotive collision repair processes. These technologies enable technicians to take accurate measurements of damaged vehicles, providing detailed digital blueprints for precise repairs.

By integrating these advanced tools, automotive body shops can achieve unparalleled structural repair precision. This not only enhances the quality of repairs but also ensures that vehicles return to their original state or even better. Such technological integration facilitates efficient navigation through complex repair processes, making auto dent repair and automotive collision repair more effective and consistent.

– Discussion on the use of modern tools and equipment for precise structural assessments.

In today’s digital age, shops leverage modern tools and equipment to achieve unparalleled precision in structural repair. Advanced technologies like 3D scanning and laser measurement systems have transformed how professionals assess and address vehicle bodywork damage. These innovative solutions capture intricate details, ensuring every bump, dent, and crack is accurately documented for precise repairs. For instance, 3D scanners can create detailed digital models of a vehicle’s body, allowing technicians to virtually inspect and compare against original factory specifications.

This technological advancement not only enhances the accuracy of structural repair but also streamlines the process. Digital measurements reduce human error, enabling efficient work flows in both bumper repair and auto body restoration scenarios. As a result, shops can deliver superior quality repairs with enhanced speed and consistency, meeting or exceeding industry standards across various vehicle models.

– Examples of laser scanners, 3D modeling software, and digital measuring tools.

In today’s digital age, shops leverage advanced technologies like laser scanners, 3D modeling software, and digital measuring tools to achieve unparalleled accuracy in structural repair precision. These innovative solutions enable technicians to capture detailed measurements of damaged areas with remarkable exactness, ensuring each repair is tailored to specific needs. For instance, laser scanners can rapidly generate high-resolution point clouds of complex surfaces, providing a comprehensive digital blueprint for precise restoration work.

Moreover, 3D modeling software allows for the creation of virtual prototypes, enabling visual analysis and simulation before actual repairs commence. This approach not only minimizes errors but also facilitates effective communication between repair teams and clients. By integrating these technologies, auto repair services, including specialized car scratch repair and automotive collision repair, can maintain high standards of quality, ensuring every job is completed with meticulous structural repair precision.

Shops are leveraging advanced technology to ensure structural repair precision on every job. Integration of laser scanners, 3D modeling software, and digital measuring tools allows for accurate measurements, enhancing the quality and efficiency of repairs. By embracing these modern solutions, shops can consistently deliver exceptional results, ensuring customer satisfaction and maintaining the integrity of structures.