Spectrophotometer color matching is a highly precise method for exact color reproduction in automotive and cosmetic sectors. By gauging material reflectance or absorbance at specific wavelengths, it generates spectral curves compared to standards. This process ensures flawless color matching in auto body repairs, considering factors like hue, saturation, brightness, luminance, and light source influence. Advanced features like auto calibration and multi-angle measurements make it ideal for professional and DIY projects, enhancing aesthetics and resale value. Best practices include regular calibration, standardized lighting, controlled environments, and digital color databases.

Uncover the precise art of spectrophotometer color matching with our comprehensive guide. Learn how these advanced instruments measure color with unparalleled accuracy, from understanding fundamental principles to exploring sophisticated techniques. Discover real-world applications spanning industries like manufacturing and design, where accurate color replication is paramount. This guide offers best practices, insights into instrument calibration, and tips for achieving consistent, reliable results in your color matching endeavors.

- Understanding Spectrophotometer Color Matching: The Basics

- Advanced Techniques for Accurate Color Measurement

- Real-World Applications and Best Practices

Understanding Spectrophotometer Color Matching: The Basics

Spectrophotometer color matching is a precise method used to ensure accurate and consistent color reproduction in various industries, including automotive and cosmetic manufacturing. It involves measuring the reflectance or absorbance of light by materials at specific wavelengths using a spectrophotometer instrument. This process allows for detailed analysis of colors, enabling technicians to match hues with incredible accuracy.

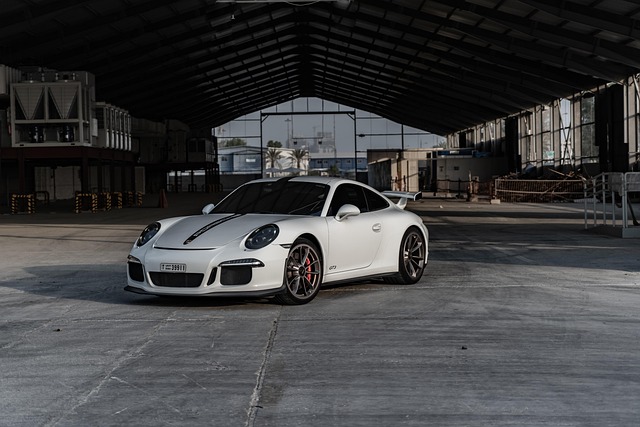

The basic principle behind spectrophotometer color matching is to compare a sample’s spectral curve—a graph representing its interaction with light across different wavelengths—to that of a known standard. By evaluating factors like hue, saturation, and brightness at various angles and under controlled lighting conditions, professionals can reproduce colors identically or closely match them for applications like car bodywork services, auto body repair, and auto dent repair, ensuring top-quality results every time.

Advanced Techniques for Accurate Color Measurement

In the quest for precise color matching, especially in industries like auto painting and vehicle dent repair, advanced spectrophotometer color matching techniques have emerged as indispensable tools. These sophisticated methods go beyond basic color measurement by considering not just hue and saturation but also luminance and light source influence. By employing technologies such as auto calibration and multi-angle measurements, professionals can achieve a level of accuracy that was once unattainable. This ensures that every repair or customization accurately matches the original vehicle’s color, be it for auto maintenance or intricate restoration work.

Furthermore, modern spectrophotometers often incorporate advanced algorithms that account for variations in light conditions and material properties. This capability is particularly crucial when dealing with diverse automotive finishes, from glossy to matte, which can reflect light differently under various lighting setups. These innovations not only streamline the color matching process but also guarantee a flawless finish, elevating the quality of both professional and DIY auto maintenance endeavors.

Real-World Applications and Best Practices

In various industries, spectrophotometer color matching plays a pivotal role in achieving precise and consistent results. Beyond the realm of scientific research, this technique finds extensive applications in sectors such as automotive repair, car body repair, and vehicle body restoration. Professionals in these fields rely on spectrophotometry to ensure that replacement parts match the original colors exactly, preserving the vehicle’s aesthetic appeal and resale value. For instance, in automotive repair, a spectrophotometer is instrumental in mixing the right pigments to match not just the car’s exterior paint but also intricate details like trim and interior components.

Adhering to best practices ensures optimal accuracy during spectrophotometer color matching. These include calibrating instruments regularly, using standardized lighting conditions, and maintaining controlled environments to minimize external variables. Additionally, employing industry-approved standards for color measurement and cross-referencing with digital color databases enhances precision. For vehicle body repair, this might involve capturing detailed color profiles of damaged areas before repair, comparing them post-restoration using the spectrophotometer, and making adjustments as needed. These practices collectively contribute to the development of a robust spectrophotometer color matching protocol that benefits both professionals and consumers alike in various industries.

In conclusion, mastering spectrophotometer color matching techniques empowers professionals across industries to achieve precise, consistent results. From understanding fundamental concepts to exploring advanced methodologies, this guide has equipped readers with the knowledge to navigate real-world applications effectively. By adhering to best practices and leveraging these techniques, accurate color measurement becomes a reliable cornerstone for various sectors, ensuring quality control and enhancing product consistency.