Body panel insulation is a critical component for automotive protection, regulation, and aesthetics. Common issues include accident damage, moisture exposure, and age-related deterioration, compromising performance and quality. Before repair or restoration, a thorough inspection using specialized tools and PPE is essential. This involves visually assessing damage, cleaning surfaces, checking hardware, and confirming material compatibility to ensure long-lasting, optimal results in vehicle body panel maintenance and repair.

Before installing body panel insulation, a thorough inspection is crucial. This step ensures optimal performance and prevents future issues. Our guide helps you navigate through the process, offering insights into understanding body panel insulation—its role, common problems, and importance in vehicle construction. We equip you with essential tools and safety measures, followed by a comprehensive checklist to guarantee a meticulous inspection. Optimize your installation with these expert tips tailored for body panel insulation.

- Understanding Body Panel Insulation: Its Role and Common Issues

- Preparation: Tools and Safety Measures for Effective Inspection

- Comprehensive Inspection Checklist: Ensuring Optimal Performance Before Installation

Understanding Body Panel Insulation: Its Role and Common Issues

Body panel insulation plays a crucial role in automotive construction, acting as a protective barrier between the car’s structural components and the external elements. It helps regulate temperature, reduces noise, and enhances overall vehicle performance. In auto collision repair and car body restoration, ensuring proper body panel insulation is essential for achieving a seamless finish and optimal vehicle functionality.

Common issues with body panel insulation include damage from accidents, exposure to moisture, and age-related deterioration. Over time, insulation can become fragmented or lose its effectiveness, leading to poor heat retention, increased noise levels, and even structural weaknesses. For instance, paintless dent repair techniques often require inspecting the underlying insulation to ensure any dents are addressed thoroughly, as hidden damage could compromise the panel’s integrity and overall car body restoration quality.

Preparation: Tools and Safety Measures for Effective Inspection

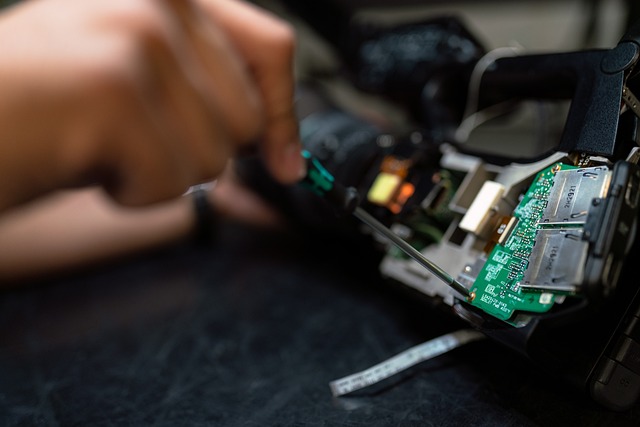

Before diving into the inspection process, it’s crucial to gather the necessary tools and ensure a safe workspace. For an effective body panel insulation check, you’ll require specific equipment tailored for this task. Invest in a good set of magnifying glasses or a flashlight with adjustable focus to examine intricate details. Additionally, a meter or gauge designed for measuring insulation resistance (ohmmeter) is essential for gauging the condition of the material.

Safety should be your top priority. Wear appropriate personal protective equipment (PPE), including gloves and safety goggles, to shield yourself from potential hazards. As you’ll be handling insulators, ensure a well-ventilated area to prevent any buildup of harmful fumes. A collision repair shop environment is ideal for this preparation phase, offering both the required tools and controlled conditions to meticulously inspect body panel insulation before installation, ensuring top-notch auto body painting results.

Comprehensive Inspection Checklist: Ensuring Optimal Performance Before Installation

Before installing body panel insulation in your vehicle restoration or vehicle body repair project, conduct a thorough inspection using a comprehensive checklist. This process ensures optimal performance and long-lasting results. Start by visually examining the panel for any signs of damage, warping, or deformity. Check for proper alignment with adjacent panels, ensuring seamless integration. Look for gaps or spaces that could compromise insulation effectiveness.

Next, inspect the panel’s surface for cleanliness and debris removal. Dust, grease, and other contaminants can affect adhesion. Verify that all hardware, such as screws and brackets, is secure and in good condition. Check for any signs of corrosion, especially in older vehicle body repairs. Lastly, ensure that the insulation material is suitable for your application, considering factors like temperature resistance and compatibility with the vehicle’s unique requirements. This meticulous approach guarantees a superior finish in both vehicle restoration and body panel repair endeavors.

Before installing body panel insulation, a thorough inspection is key to ensuring optimal performance. By following the comprehensive checklist and taking appropriate safety measures, you can effectively identify and address common issues, guaranteeing a robust and efficient insulation system. This meticulous process is an essential step in maximizing energy efficiency and vehicle performance, making your inspection an invaluable part of any automotive project.