Factory Tolerance Restoration (FTR) is a specialized auto body repair process that adjusts vehicle components to their original factory specifications after damage or a collision. Essential for modern vehicles with advanced materials, FTR ensures precise tolerances for optimal performance and structural integrity. Beyond automotive repairs, FTR is used in various manufacturing sectors to maintain quality control, prevent misalignments, and promote efficient operations, extending the lifespan of products and enhancing their safety and aesthetic appeal.

Factory Tolerance Restoration (FTR) is a game-changer in industrial manufacturing, offering significant advantages for maintaining structural integrity. This process involves precision adjustments to components during production, ensuring they meet tight tolerances. By restoring these tolerances, FTR enhances the overall quality and reliability of products. The article delves into the mechanics of FTR, explores its key benefits, and highlights practical applications, demonstrating how it revolutionizes industrial processes and ensures long-lasting structural stability.

- Understanding Factory Tolerance Restoration

- Restoring Structural Integrity: The Key Benefits

- Practical Applications and Impact on Industrial Processes

Understanding Factory Tolerance Restoration

Factory Tolerance Restoration (FTR) is a specialized process that aims to realign and adjust components within a vehicle’s structure to their original factory specifications after a collision or damage. It involves meticulous techniques to restore the precise tolerances between various parts, ensuring they function harmoniously as designed. This process is particularly crucial in modern vehicles, where intricate designs and advanced materials require exacting precision for optimal performance and structural integrity.

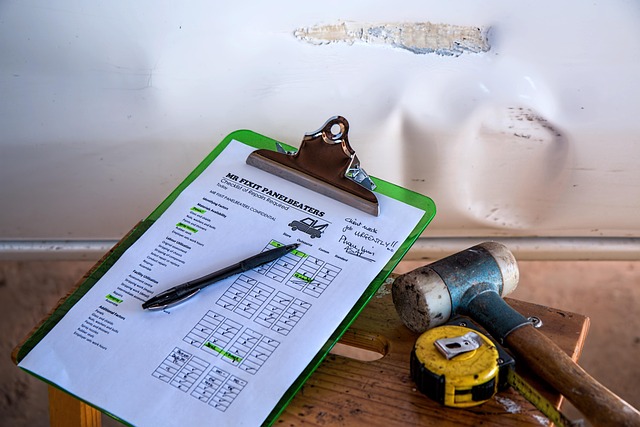

In the event of an auto body painting or vehicle collision repair, FTR becomes an essential step to ensure that all components, from paneling to mechanical systems, operate seamlessly. Car repair services employing FTR techniques can accurately address issues related to misaligned panels, compromised chassis integrity, or off-spec engine components, ultimately enhancing the overall quality and longevity of the repaired vehicle.

Restoring Structural Integrity: The Key Benefits

Restoring structural integrity is a critical aspect of factory tolerance restoration, offering numerous advantages for manufacturers and vehicle owners alike. By accurately recreating the original design specifications, this process ensures that every component aligns seamlessly, enhancing overall stability and performance. This meticulous approach, often applied to car body restoration or collision repair services, addresses any deviations caused by wear and tear, accidents, or subpar maintenance, resulting in a vehicle with superior structural integrity.

Factory tolerance restoration techniques are invaluable for maintaining the precision engineering that goes into modern vehicles. It allows for exacting repairs and adjustments, particularly in complex areas like suspension systems and chassis frames. This attention to detail not only improves safety but also extends the lifespan of the vehicle body repair process, ensuring a more durable and reliable ride.

Practical Applications and Impact on Industrial Processes

Factory Tolerance Restoration (FTR) has practical applications that extend far beyond the assembly line, significantly impacting various industrial processes and sectors. In the automotive industry, for example, FTR plays a pivotal role in auto detailing and automotive collision repair. By precisely restoring tolerances to original specifications, vehicle body shops can ensure flawless finishes, precise panel gaps, and overall structural integrity after repairs or modifications. This not only enhances the aesthetic appeal of vehicles but also guarantees their safety and reliability on the road.

Beyond the automotive realm, FTR is crucial in maintaining quality control across diverse manufacturing environments. From precision engineering to aerospace production, restoring factory tolerances ensures that components interlock seamlessly, preventing costly misalignments or failures down the line. This practice, akin to fine-tuning a machine, allows for more efficient operations and helps prevent issues commonly encountered in auto detailing or vehicle body shop settings, such as wobbly parts, irregular surfaces, and structural weaknesses.

Factory Tolerance Restoration (FTR) plays a pivotal role in enhancing structural integrity within industrial settings. By understanding and implementing FTR, manufacturers can achieve significant improvements in precision and quality control. The key benefits, including increased component compatibility and reduced assembly errors, lead to more efficient production processes and improved overall product performance. This article has explored the practical applications of FTR, demonstrating its value as a game-changer for modern manufacturing, particularly in today’s digital era where precision is paramount.