TL;DR:

Mastering sectioning procedures is key for auto professionals, enabling efficient cleaning, inspection, and repair. Dividing vehicles into body panels, chassis, and mechanical components allows specialized care. This systematic approach boosts service quality and inventory management, mirroring luxury car manufacturers' assembly lines. Proper tool storage using modular chests or wall racks ensures flawless sectioning. Regular cleaning, polishing, and protection from sunlight and extreme temperatures maintain sectional furniture's integrity over time. Separate storage for each section minimizes wear and tear in confined spaces like automotive body shops.

In the realm of organized storage, understanding and maintaining sectioning procedures is paramount. This comprehensive guide delves into the heart of efficient organization strategies, focusing on tools, maintenance, and storage techniques for optimal results. From selecting the right tools to implementing best practices, we offer a detailed roadmap to ensure your sectioning systems remain robust and well-maintained over time. Explore these insights to revolutionize your organizational approach.

- Understanding Sectioning Procedures: A Comprehensive Overview

- Essential Tools for Efficient Section Maintenance and Storage

- Best Practices for Long-Lasting Sectional Care and Organization

Understanding Sectioning Procedures: A Comprehensive Overview

Understanding sectioning procedures is paramount for anyone involved in automotive maintenance or restoration, whether it’s a simple car wash or complex Mercedes-Benz repair. It involves meticulously dividing an automobile into distinct sections to facilitate efficient and thorough cleaning, inspection, or repair. This systematic approach ensures every component, from the engine bay to the interior, receives equal attention, thereby enhancing the overall quality of services provided in auto detailing or restoration processes.

For instance, a skilled technician performing a car restoration will section off areas like the body panels, chassis, and mechanical components separately. Such division enables them to address each section with specialized care, be it removing stubborn rust in a specific panel or rebuilding an engine with precision. This method is also advantageous for inventory management, as it allows mechanics to track tools and parts more efficiently, especially in a well-organized garage setting, akin to the meticulous assembly line of a Mercedes-Benz production facility.

Essential Tools for Efficient Section Maintenance and Storage

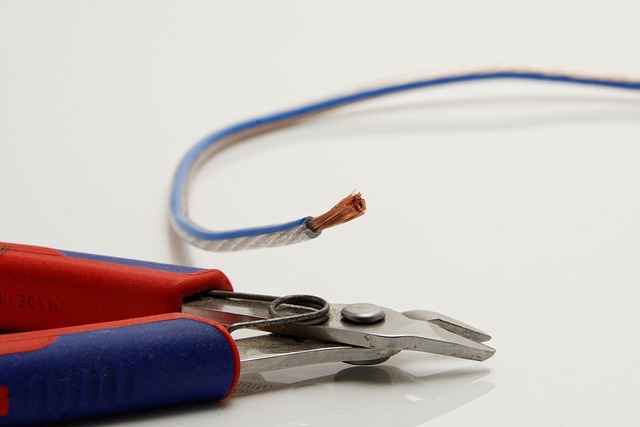

Maintaining and storing sections efficiently is a cornerstone of any professional auto body services or vehicle dent repair operation. The right tools play a pivotal role in ensuring that sectioning procedures are executed flawlessly. An ideal toolkit for this purpose should include specialized equipment designed to handle various tasks, from precise cutting and shaping to meticulous finishing.

Consider investing in high-quality shears, hand tools, and power tools tailored for auto collision center work. Shears with adjustable settings allow for clean cuts, while robust hand tools enable detailed work during the sectioning process. Power tools, such as angle grinders and sanders, streamline the smoothing and shaping stages, saving time and reducing human error in vehicle dent repair. Efficient storage solutions, like modular tool chests or wall-mounted racks, further enhance accessibility, ensuring that the right tools are readily available when needed for any sectioning procedure.

Best Practices for Long-Lasting Sectional Care and Organization

Proper maintenance and storage are key to ensuring your sectional furniture remains in top condition for years to come. Start by regularly cleaning and polishing the surfaces with appropriate cleaners, following the manufacturer’s guidelines. Protecting it from direct sunlight and extreme temperatures will prevent fading and warping.

Organize your storage space wisely. Use breathable covers to protect against dust and pests. Store sections separately if possible, especially in an automotive body shop or car body restoration environment where spaces are confined and potential for damage from vehicles (like dent repair) exists. This minimizes wear and tear during handling and maintains the overall aesthetics of each piece, like those found in a bustling home or even a professional setting.

Sectioning procedures are essential for organized and efficient maintenance, and proper tool storage is key to preserving your sectional furniture over time. By understanding these processes and implementing best practices, you can ensure your sections remain in top condition, enhancing their longevity and overall aesthetic appeal. Remember, regular care and a well-organized storage system are the cornerstones of successful sectional maintenance.