Tesla composite repair demands specialized techniques due to the unique nature of materials like carbon fiber and fiberglass. Skilled technicians use precise methods involving cutting, layering, and curing composites to restore structural integrity and aesthetic appeal after weather or impact damage. A meticulous process including assessment, preparation, mixing resin, painting, and sanding ensures optimal results matching Tesla's original finish while preserving vehicle value and performance.

Tesla vehicles are renowned for their advanced design and innovative materials, with composite panels being a key feature. When these panels suffer weather or impact damage, specialized repair techniques are required. This article delves into the world of Tesla composite repair, offering a comprehensive guide to restoring these unique automotive surfaces. From understanding the material properties to following precise steps and best practices, it’s an essential read for anyone looking to maintain their Tesla’s pristine condition.

- Understanding Tesla Composite Materials and Their Unique Repair Process

- Step-by-Step Guide to Composite Repair for Weather and Impact Damage

- Best Practices and Tips for Ensuring Optimal Results After Tesla Composite Repair

Understanding Tesla Composite Materials and Their Unique Repair Process

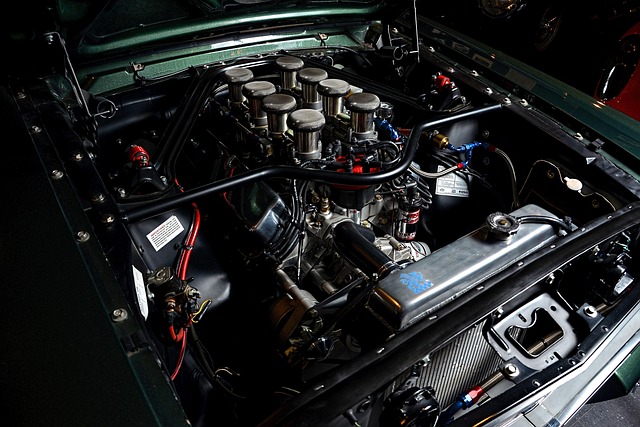

Tesla vehicles are renowned for their innovative use of composite materials in construction, which offers both lightweight and enhanced structural integrity. These advanced composites, including carbon fiber and fiberglass, form a significant part of Tesla’s design philosophy, ensuring superior performance and efficiency. However, understanding that these materials differ from traditional metal, it’s crucial to explore the specialized approach required for Tesla composite repair after weather or impact damage.

When a Tesla experiences damage due to weather conditions like storms or flooding, or as a result of a collision at a trusted auto repair shop or collision repair center, the repair process becomes more intricate. Standard auto repair techniques may not apply to these composite materials without specialized training and equipment. Skilled technicians employ unique methods tailored for Tesla composite repair, ensuring precision and minimal impact on the vehicle’s overall strength and aesthetics. This involves meticulous preparation, precise cutting, and careful layering of composite patches before curing them with specific resins, resulting in a restoration that closely matches the original material.

Step-by-Step Guide to Composite Repair for Weather and Impact Damage

Repairing Tesla composite damage from weather or impact requires a meticulous approach. Here’s your step-by-step guide to achieving flawless results:

1. Assess the Damage: Carefully inspect the affected area, identifying cracks, chips, or delaminations. This step is crucial for pinpointing the extent of repair needed and ensuring no underlying structural issues are overlooked. For complex damage, consider seeking expert advice from a specialized Tesla auto collision center.

2. Gather Materials: Procure high-quality composite repair kits designed specifically for Tesla models. These kits typically include resins, hardeners, fillers, and finishing products. Ensure compatibility with your Tesla’s composite materials to guarantee optimal bonding and long-lasting repairs. Don’t forget protective gear; safety comes first!

3. Preparation is Key: Thoroughly clean the damaged area using automotive-grade solvents or degreasers to remove grease, dirt, or debris. Sand the surface lightly to create a slightly rough texture, enhancing adhesive bond strength. Prime the composite with an appropriate primer to ensure compatibility between the repair material and the existing composite.

4. Repair Process: Apply the resin and hardener according to manufacturer instructions, mixing them carefully. Fill the damaged area with the mixture, using tools like putty knives or tampons for precise application. Allow it to cure as per recommended times. Once cured, lightly sand the repair area to blend it seamlessly with the surrounding composite.

5. Finishing Touches: Apply a suitable auto body paint that matches your Tesla’s original finish. Use high-quality brushes and spray equipment for even coating. Allow the paint to dry completely, then inspect for any imperfections. A final clear coat can enhance durability and provide a glossy finish, making the repair nearly indistinguishable from the original composite.

Best Practices and Tips for Ensuring Optimal Results After Tesla Composite Repair

When undertaking Tesla composite repair after weather or impact damage, adhering to best practices is paramount for achieving optimal results. Firstly, ensure that the work is performed by a certified professional with expertise in composite materials, as this specialized knowledge is crucial for accurate repairs that match the vehicle’s original finish. Proper surface preparation is another key step; thoroughly cleaning and decontaminating the damaged area before repair to prevent any contaminants from affecting the final outcome.

Additionally, using high-quality composite repair kits specifically designed for Tesla models will enhance longevity and visual appeal. During the repair process, maintain a consistent pressure and angle while filling and sanding to ensure even application. Finally, for a seamless finish that blends perfectly with the surrounding bodywork, multiple thin coats of paint are recommended over one thick layer. Remember, meticulous attention to detail during each step guarantees a top-notch car collision repair or car restoration outcome, restoring your Tesla to its pre-damage condition.

Tesla composite repair is a specialized process that requires a deep understanding of the unique material properties. By following the step-by-step guide and best practices outlined in this article, you can effectively address weather or impact damage to your Tesla’s composite body panels. Remember, proper preparation and adherence to optimal repair techniques ensure not only structural integrity but also maintain the vehicle’s aesthetic appeal, making it a valuable resource for anyone looking to preserve their Tesla’s condition post-damage.