Complex damage in metal fabrication collision repair involves intricate structural issues like dents, cracks, misaligned panels, and compromised welds. Skilled technicians use advanced techniques, tools (CAD, robotic welding), and specialized equipment (hydraulic presses, computer-controlled cutting) to assess, realign, replace, and restore vehicle components, ensuring structural integrity and high-quality finishes that meet manufacturer standards. Digital era advancements like laser cutting and 3D printing further streamline repairs, minimizing waste and restoring intricate details for peaceful minds and beautifully restored vehicles.

In the realm of metal fabrication collision repair, handling complex damage requires a delicate balance between skill and technology. As vehicles become increasingly sophisticated, so does the nature of collisions, presenting challenges that demand specialized techniques. This article explores how professionals navigate intricate metal fabrication collision repairs, from understanding unique damage patterns to leveraging advanced technologies for precise, efficient outcomes. Discover the game-changing strategies that ensure every repair stands as a testament to automotive craftsmanship.

- Understanding Complex Damage in Metal Fabrication Collision Repair

- Specialized Techniques for Handling Challenging Cases

- The Impact and Benefits of Advanced Technology in Repairs

Understanding Complex Damage in Metal Fabrication Collision Repair

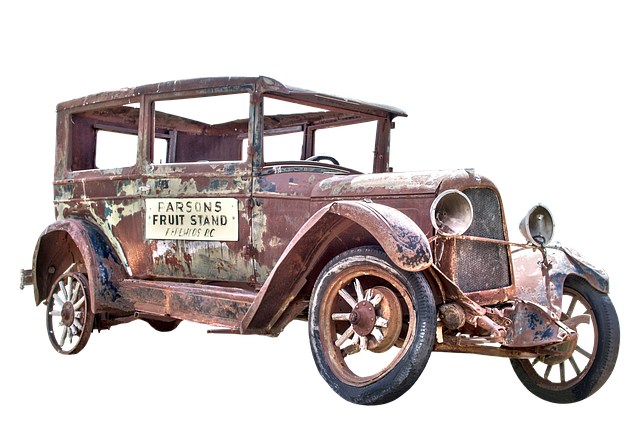

Complex damage in metal fabrication collision repair refers to intricate and multi-faceted issues that arise when a vehicle undergoes significant structural trauma. This type of damage often involves not just visible dents and cracks, but also misaligned panels, compromised welds, and hidden internal stress concentrations. Understanding these complexities is crucial for accurate assessment and successful restoration in an auto collision center.

Metal fabrication techniques play a vital role in addressing complex damage. Skilled technicians employ a combination of specialized tools and precision-based methods to realign components, replace damaged parts, and rebuild structural integrity. Effective auto maintenance requires meticulous attention to detail, ensuring that every aspect of the car body repair is handled with care to prevent further complications or long-term structural failures.

Specialized Techniques for Handling Challenging Cases

In the realm of metal fabrication collision repair, challenging cases often involve complex damage that requires specialized techniques to restore vehicles to their pre-accident condition. Skilled technicians in automotive body shops and car body shops employ advanced methods to handle intricate repairs, ensuring precision and structural integrity. These techniques range from computer-aided design (CAD) systems for accurate measurements and adjustments, to robotic welding for consistent and precise joint formation.

Additionally, specialized equipment such as hydraulic presses and computer-controlled cutting tools enable the removal of damaged components while preserving the integrity of surrounding areas. The use of these advanced tools and techniques in automotive repair not only accelerates the restoration process but also guarantees a high-quality finish that meets or exceeds original manufacturer standards. This meticulous approach ensures that each vehicle, regardless of the severity of damage, receives expert care in top-tier automotive body shops.

The Impact and Benefits of Advanced Technology in Repairs

In today’s digital era, advanced technology has revolutionized metal fabrication collision repair processes. Sophisticated tools like laser cutting and 3D printing enable precise, efficient, and accurate repairs, even for complex damage. These innovations not only enhance the speed of auto frame repair but also ensure minimal material waste, contributing to a more sustainable approach in car scratch repair.

Furthermore, technology-driven methods such as computer-aided design (CAD) software and robotic welding systems offer unparalleled precision during dent removal. This not only improves the structural integrity of vehicles but also allows for intricate details to be restored, enhancing the overall quality of collision repair services. As a result, metal fabrication collision repair shops are better equipped to handle a wide range of damages, from minor dents to significant structural issues, providing owners with peace of mind and beautifully restored vehicles.

In the realm of metal fabrication collision repair, complex damage demands specialized techniques and advanced technology. By understanding intricate issues and employing innovative solutions, professionals can expertly restore vehicles to their pre-accident condition. Through tailored approaches and the integration of modern tools, this industry sets the standard for quality and precision in challenging repair scenarios.