Spot weld bonding repair is a precise, eco-friendly method joining metal surfaces that minimizes energy input into surrounding material, reducing greenhouse gas emissions and resource waste. Ideal for auto collision and vehicle body repairs, this technique enhances structural integrity for longer-lasting, more durable fixes, lowering the need for frequent body repair and contributing to a greener automotive industry with less waste and a smaller carbon footprint.

Spot weld bonding techniques offer a sustainable solution for manufacturing, with significant environmental benefits. This article explores how understanding and adopting spot weld bonding repair can reduce waste and enhance material efficiency. By minimizing excess materials and focusing on precise repairs, this method lowers energy consumption and cuts emissions. It’s a game-changer in the industry, promoting sustainability without compromising quality or durability. Discover how these techniques contribute to a greener future for manufacturing processes.

- Understanding Spot Weld Bonding Repair and Its Environmental Impact

- Reduced Waste and Material Efficiency

- Lower Energy Consumption and Emission Savings

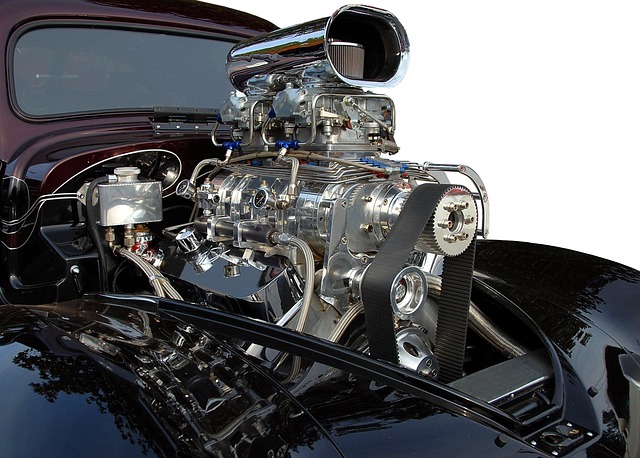

Understanding Spot Weld Bonding Repair and Its Environmental Impact

Spot weld bonding repair is a precise technique that involves joining two metal surfaces with a localized heat source and pressure. Unlike traditional welding methods, this process only affects the immediate area around the joint, minimizing heat input into the surrounding material. This targeted approach not only reduces energy consumption but also minimizes the risk of warping or damaging the overall structure during auto collision repair or vehicle body repair processes.

The environmental impact of spot weld bonding is significant, especially in the context of auto glass repair and general vehicle maintenance. By reducing the amount of heat and energy required, this technique lowers greenhouse gas emissions and conserves natural resources. Furthermore, spot weld bonding can enhance the structural integrity of repairs, leading to longer-lasting and more durable auto collision repairs. This longevity translates into less frequent vehicle body repair needs, contributing to a greener and more sustainable automotive industry.

Reduced Waste and Material Efficiency

Spot weld bonding techniques offer a sustainable solution for various automotive repairs, including spot weld repair and dent removal. By utilizing this method, car repair services can significantly minimize waste generation and enhance material efficiency. Traditional welding processes often result in substantial scrap material due to their invasive nature, but spot weld bonding is different. This non-destructive approach allows technicians to apply precise pressure and heat to create a strong bond without cutting or melting away at the surrounding material.

As a result, auto body services can reduce the amount of scrap metal generated, which has positive environmental implications. The technique’s precision also means less material is required to make repairs, leading to cost savings and fewer resources consumed. This efficiency benefit extends beyond car repair services; it contributes to a greener automotive industry overall, with reduced waste and a lower carbon footprint.

Lower Energy Consumption and Emission Savings

The process of spot weld bonding is renowned for its energy-efficient nature, which brings significant environmental advantages compared to traditional welding methods. When repairing vehicles, such as cars or fenders, this technique demands less energy input to achieve a robust and durable bond. Unlike conventional welding, spot weld bonding doesn’t require excessive heat or prolonged energy consumption, thus reducing the overall carbon footprint of vehicle repair services.

By minimizing the energy needed for heating and melting metals, spot weld bonding contributes to lower emission levels. This is especially notable in industrial settings where multiple vehicles undergo repairs daily. The reduced energy consumption translates to a smaller environmental impact, making it an eco-friendly alternative for car paint repair and fender repair processes.

Spot weld bonding repair offers a sustainable solution for manufacturers, as it significantly reduces environmental impact. By minimizing waste and optimizing material usage, this technique promotes resource efficiency. Additionally, lower energy consumption and resultant emission savings contribute to a greener production process. Embracing spot weld bonding repair is not just a strategic decision but also an environmentally responsible one.