Sound deadening materials are crucial for creating comfortable and safe automotive environments during collision repair. By understanding their noise absorption and durability, auto shops can strategically install them to minimize echo, reverberation, and loud machinery sounds. Effective inspection involves thorough coverage from door panels to trunk linings, ensuring proper alignment and security with secure fasteners. Performance evaluation uses sound level meters for accurate noise reduction assessments before and after installation, while visual inspections verify fastening and complete coverage, following manufacturer guidelines for optimal results in new or refurbished vehicles.

“Uncover the secrets to ensuring optimal noise control with an in-depth guide to inspecting sound deadening material installations. Effective soundproofing is crucial for creating peaceful environments, from homes to commercial spaces. This article delves into the significance of understanding sound deadening materials and their role in reducing noise pollution. We’ll walk you through a systematic process of inspecting installed materials, providing essential tools and techniques to measure their performance and ensure they live up to their promise of quietude.”

- Understanding Sound Deadening Materials and Their Role in Noise Reduction

- Steps to Effectively Inspect Installed Sound Deadening Materials

- Measuring Performance: Tools and Techniques for Assessing Sound Deadening Efficacy

Understanding Sound Deadening Materials and Their Role in Noise Reduction

Sound deadening materials play a pivotal role in noise reduction within automotive spaces, particularly in collision repair shops and auto repair facilities. These specialized products are designed to absorb sound waves, minimizing echo and reverberation, which leads to quieter interiors. In the context of vehicle repairs, where loud machinery and impact sounds are common, effective sound deadening is essential for creating a more comfortable and safe environment for both workers and customers.

By understanding the unique properties of various sound deadening materials, auto repair shops can make informed decisions when selecting products. Different materials offer varying levels of noise absorption and durability, catering to specific needs in different areas of the shop, such as engine bays or workshop floors. This strategic installation of sound-deadening solutions ensures not only a quieter atmosphere but also enhances the overall efficiency of collision repair and vehicle maintenance processes.

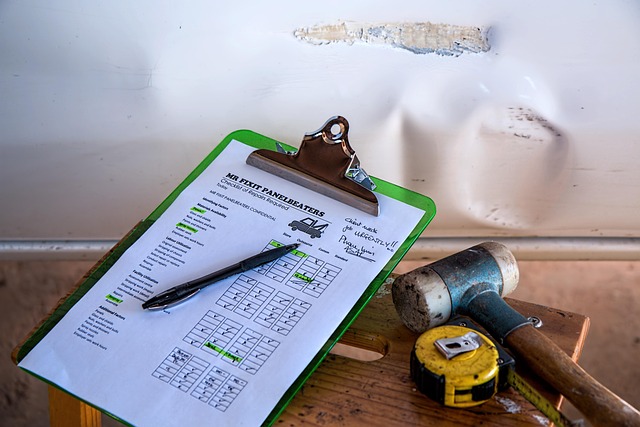

Steps to Effectively Inspect Installed Sound Deadening Materials

To effectively inspect installed sound deadening materials, begin by examining the coverage and placement of the material within the vehicle’s interior. Ensure that every nook and cranny is adequately covered, including hard-to-reach areas like door panels, trunk linings, and ceiling insulations. This step is crucial in achieving optimal sound reduction across the board.

Next, check for proper alignment and security of the sound deadening materials. The layers should fit tightly against the underlying surfaces without any gaps or misalignments. In a vehicle repair or body shop service like Mercedes Benz repair, it’s essential to verify that the materials are securely fastened using appropriate adhesives or clips to prevent shifting during driving, thereby ensuring their effectiveness in noise cancellation.

Measuring Performance: Tools and Techniques for Assessing Sound Deadening Efficacy

Evaluating sound deadening materials’ performance is a meticulous process that requires specialized tools and techniques. One common method involves using sound level meters to measure noise reduction before and after installation. These devices, calibrated to industry standards, can accurately assess the effectiveness of the materials in mitigating sound transmission. By placing the meter at various points within the vehicle, from the cabin to the engine bay, professionals can identify areas where additional treatment might be needed.

Additionally, visual inspection plays a crucial role. Technicians look for signs of proper installation, ensuring that the sound deadening material is securely fastened and covers all designated surfaces. In a vehicle body shop, for instance, this includes checking the interior panels, floors, and even hard-to-reach spaces around the engine and fender repair areas. Proper adherence to manufacturer guidelines ensures optimal performance, contributing to a quieter driving experience in both new and refurbished vehicles.

Inspecting the effectiveness of sound deadening material installation is crucial for ensuring optimal noise reduction in any environment. By understanding these materials and following a structured inspection process, you can accurately assess their performance. Utilizing appropriate measurement tools and techniques allows for quantifying the sound-dampening capabilities, guaranteeing that your space benefits from enhanced acoustic comfort. Regular inspections are key to maintaining these materials’ efficacy over time.