Electric vehicles (EVs) present unique challenges in auto frame repair due to their complex designs featuring lightweight composites and high-strength steels, which require specialized tools and techniques for precise alignment. EV structural elements like battery packs demand adapted repair strategies while preserving safety standards and performance capabilities without compromising advanced machine integrity. Auto body shops must stay current with latest technologies to effectively handle these evolving challenges in auto frame repair for EVs.

The rise of electric vehicles (EVs) brings unique challenges for auto frame repair. Unlike conventional cars, EVs possess distinct frame structures, integrating crucial components like battery packs and intricate wiring harnesses. This article delves into the complexities of EV frame repair, exploring the differences in design and key components that pose specific issues. We’ll discuss modern innovations, including advanced repair techniques and technology-driven solutions tailored to meet the demands of this evolving automotive landscape.

- Understanding the Unique Frame Structure of Electric Vehicles

- – Exploring the differences in frame design compared to conventional vehicles

- – Key components and their importance in EV structure

Understanding the Unique Frame Structure of Electric Vehicles

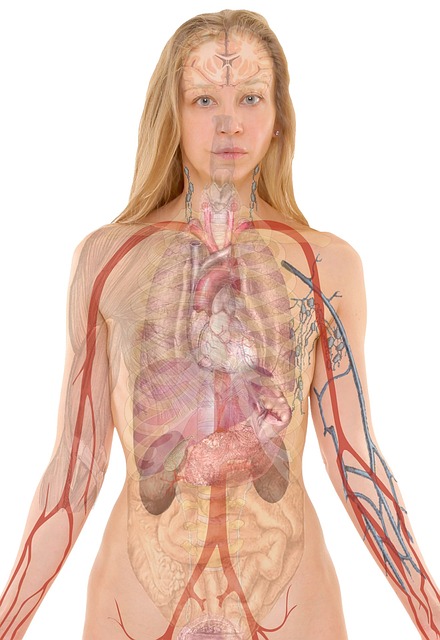

Electric vehicles (EVs) present unique challenges when it comes to auto frame repair compared to their internal combustion engine counterparts. These vehicles often feature more complex frame designs, incorporating advanced materials like lightweight composites and high-strength steels. The frame serves not only as a structural backbone but also houses crucial components such as battery packs and electric motors, which require precise alignment and stability during any repair process.

Understanding the intricate nature of EV frames is paramount for skilled auto body repair technicians. In automotive collision repair, the goal is to accurately straighten and realign the frame while maintaining the vehicle’s safety standards and performance capabilities. This involves specialized tools and techniques tailored for electric vehicles, ensuring that repairs are both effective and efficient, without compromising the integrity of these cutting-edge machines.

– Exploring the differences in frame design compared to conventional vehicles

Electric vehicles (EVs) present unique challenges for auto frame repair compared to their conventional counterparts. While traditional cars often feature rigid, metal frames that are easily identifiable and accessible for repairs, EVs often employ complex, lightweight materials like aluminum and composite fibers integrated into the vehicle structure. This design philosophy not only aims to reduce weight for improved efficiency but also introduces new complexities for body shops. For example, specialized tools and techniques may be required to safely disassemble and reassemble components without damaging sensitive electrical systems or high-tech sensors.

Furthermore, the location of some structural elements in EVs can differ significantly from conventional vehicles. Battery packs, for instance, might be strategically placed beneath the floorpan, requiring auto body shops to adapt their repair strategies and consider potential impacts on frame alignment and structural integrity during collision repair center operations. This shift in design demands that automotive body shops stay updated with the latest technologies and methodologies to ensure they can effectively handle these evolving challenges in auto frame repair.

– Key components and their importance in EV structure

The structure of electric vehicles (EVs) presents unique challenges for auto frame repair compared to traditional internal combustion engine cars. Key components like the battery pack, motor, and power electronics are not only crucial for vehicle functionality but also integrated deeply into the vehicle’s chassis. A critical aspect of EV design is their structural integrity, as these components add significant weight and require specialized mounting to ensure stability and safety during collisions.

Thus, auto frame repair in EVs demands a nuanced approach that considers both traditional bodywork and the specific needs of advanced power systems. While general auto dent repair or bumper repair techniques may apply, car bodywork services for EVs must also address potential issues related to corrosion, structural integrity of high-voltage components, and heat management—all while adhering to stringent safety standards unique to this emerging vehicle technology.

The unique frame structure of electric vehicles presents both challenges and opportunities for auto frame repair specialists. While the simplified design offers advantages, the specialized components and integrated technology require advanced skills and knowledge. As EV adoption continues to rise, understanding these intricacies is crucial for ensuring safe and effective repairs, paving the way for a new era in automotive maintenance.