In automotive manufacturing and collision repairs, both aluminum and steel panels are widely used for their durability, lightweight design, and corrosion resistance. Polishing these materials is crucial for enhancing aesthetics and protection. For aluminum, the goal is a smooth, reflective finish while minimizing oxidation. Steel, meanwhile, benefits from a slightly rougher initial polish to ensure better coating adhesion. Advanced polishing techniques restore damaged surfaces, achieving visually appealing pre-accident conditions, catering to customers seeking modern looks, and extending material lifespan by protecting against corrosion and staining.

Aluminum and steel panels, with their versatility and widespread use in construction and industry, can benefit greatly from polishing techniques. This article delves into the intricacies of polishing these materials, offering a comprehensive guide for achieving superior finishes. From understanding the basics of aluminum and steel, to exploring mechanical, chemical, and electrochemical polishing methods, and culminating in advanced tips for optimal results, this resource equips readers with the knowledge to achieve professional-grade polished surfaces. Discover how polishing techniques enhance aesthetics and functionality, catering to diverse applications.

- Understanding the Basics of Aluminum and Steel Polishing

- – What are aluminum and steel panels?

- – Why polish these materials?

Understanding the Basics of Aluminum and Steel Polishing

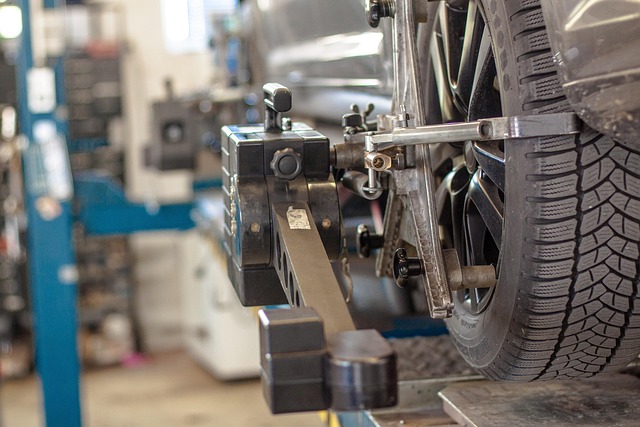

Aluminum and steel are commonly used materials in various industries, including automotive manufacturing and collision repair shops. When it comes to polishing these surfaces, understanding the unique properties of each material is key. Polishing techniques for aluminum involve creating a smooth, reflective finish while minimizing the risk of oxidation or discoloration. This process often requires specialized compounds and tools designed for its non-ferrous nature, as steel can be more susceptible to magnetic attraction during the polishing stage.

In a vehicle body shop, mastering steel polishing techniques is essential for achieving a flawless, professional finish on car bodies after collision repair. Unlike aluminum, steel benefits from a slightly rougher initial polish, allowing for better adhesion of subsequent coatings. The process involves careful selection of abrasives and polishes to avoid marring the surface while effectively removing imperfections. Proper techniques ensure the final product is not only aesthetically pleasing but also durable, enhancing the overall quality of collision repair services.

– What are aluminum and steel panels?

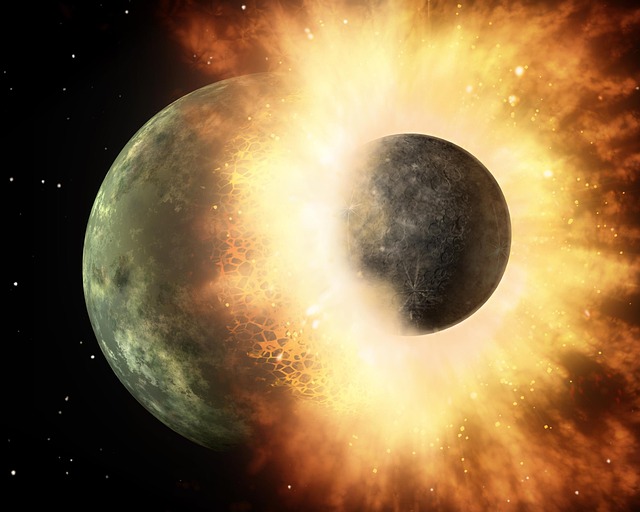

Aluminum and steel panels are common materials used in various industries, from construction to automotive manufacturing. These panels offer durability, lightweight properties, and excellent corrosion resistance, making them a preferred choice for many applications. In the context of vehicle repair services and car dent repair, aluminum and steel panels form the structural backbone of vehicles, ensuring their strength and safety.

Polishing techniques play a pivotal role in enhancing the aesthetics and finish of these panels. Whether it’s for a sleek, shiny look or to restore damaged surfaces in a vehicle body shop, polishing can transform the overall appearance. Professional car dent repair services often employ advanced polishing methods to achieve perfect results, ensuring vehicles return to their pre-accident condition, both visually appealing and structurally sound.

– Why polish these materials?

Polishing aluminum and steel panels offers a multitude of benefits for both aesthetic and functional purposes, making it an essential step in various industries, including automotive repairs. A polished surface enhances the visual appeal of vehicles, bringing out the metallic sheen and creating a sleek, modern look that many car owners desire. In the realm of auto body repair, achieving a high-quality finish is crucial to ensuring customer satisfaction and maintaining the vehicle’s overall value.

Moreover, polishing techniques play a vital role in protecting these materials from corrosion and environmental damage. Aluminum and steel panels are susceptible to oxidation and staining, which can compromise their integrity over time. Regular polishing creates a protective barrier, repelling water, dirt, and other contaminants, thus prolonging the life of the panels. For an automotive body shop or auto repair facility, this means providing clients with durable, long-lasting results that meet high aesthetic standards.

Polishing aluminum and steel panels is a meticulous art that enhances their aesthetic appeal and durability. By understanding the unique properties of these materials, you can choose the most effective polishing techniques for optimal results. Whether it’s buffing, lapping, or using specialized compounds, each method offers tailored benefits to reveal the true beauty of these versatile metals. Incorporating these polishing techniques into your workflow ensures not only a sleek finish but also improves the overall quality and longevity of aluminum and steel panels in various applications.