Tesla's rigorous Full Self-Driving (FSD) hardware inspection process ensures optimal component placement for enhanced autonomous driving safety and reliability. This meticulous evaluation includes comprehensive checks of sensors, cameras, and processing units, validating correct positioning for seamless FSD functionality. By maintaining this integrity, Tesla enables efficient auto collision repair and dent removal, minimizing downtime and restoring FSD capabilities, ultimately prioritizing safety in the evolving autonomous driving landscape.

Tesla’s commitment to advancing autonomous driving capabilities is evident through its rigorous Full Self-Driving (FSD) hardware inspection process. This intricate evaluation ensures the optimal placement of every component, from cameras to sensors, crucial for safe and efficient self-driving operations. By meticulously validating module placement, Tesla takes a significant step towards enhancing its Autopilot system, paving the way for more advanced driver assistance features and ultimately, a future of fully autonomous vehicles.

- Understanding Tesla's Full Self-Driving Hardware Inspection Process

- The Role of Hardware Inspection in Ensuring Safe Autonomous Operations

- Validating Module Placement: A Crucial Step Towards Advanced Autopilot Capabilities

Understanding Tesla's Full Self-Driving Hardware Inspection Process

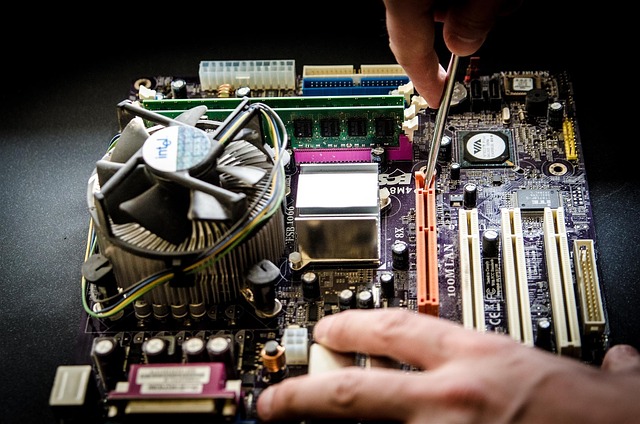

Tesla’s Full Self-Driving (FSD) hardware inspection process is a meticulous evaluation designed to ensure the optimal placement and functionality of every component in their autonomous driving system. This rigorous procedure involves a comprehensive examination of various modules, sensors, and computer systems integral to FSD capabilities. The goal is to validate that each module is correctly positioned, securely attached, and operating seamlessly with its neighbors, ensuring Tesla’s advanced driver-assistance features function flawlessly.

By conducting these inspections, Tesla not only maintains the integrity of their vehicles’ self-driving hardware but also enables efficient auto collision repair and dent removal processes. In the event of an accident or damage, a thorough understanding of module placement allows for precise replacement and restoration of FSD capabilities, ensuring drivers can benefit from enhanced safety features without extensive downtime.

The Role of Hardware Inspection in Ensuring Safe Autonomous Operations

The Tesla Full Self-Driving (FSD) hardware inspection plays a pivotal role in ensuring safe and reliable autonomous operations. It meticulously validates the placement and functionality of each module, from sensors to computers, that power FSD capabilities. This rigorous process is essential to detect any potential issues or misalignments that could compromise the vehicle’s safety while navigating complex driving scenarios. By identifying problems early on, collision repair services can be performed proactively, minimizing risks associated with autonomous systems failure.

Furthermore, regular hardware inspections contribute to maintaining optimal performance of auto glass repair and other critical components. Proper module placement ensures unobstructed sensor views and clear communication between various systems, enhancing the overall efficiency of vehicle repair services. In a rapidly evolving field like autonomous driving, these inspections serve as a safeguard, ensuring that Tesla vehicles continue to meet the highest safety standards, providing peace of mind for both passengers and road users alike.

Validating Module Placement: A Crucial Step Towards Advanced Autopilot Capabilities

Validating Module Placement is a critical process in the development of Tesla’s Full Self-Driving (FSD) capabilities. As the company continues to refine and improve its Autopilot features, ensuring precise module positioning becomes increasingly vital. This meticulous step involves a thorough inspection of each hardware component, confirming their accurate alignment and connection. By checking every sensor, camera, and processing unit, Tesla engineers can guarantee optimal performance and safety.

Proper module placement plays a significant role in enhancing the vehicle’s perception, decision-making, and overall driving experience. It ensures that sensors capture clear images and data, enabling the FSD system to interpret its surroundings accurately. With each hardware inspection, Tesla takes another step towards achieving seamless autonomous driving, transforming the automotive industry with cutting-edge car repair services that prioritize safety and precision.

Tesla’s commitment to safety is evident through its rigorous Full Self-Driving (FSD) hardware inspection process. By meticulously validating module placement, Tesla ensures that each component works harmoniously towards achieving advanced Autopilot capabilities. This meticulous inspection not only safeguards against potential malfunctions but also paves the way for a future of seamless autonomous driving, enhancing both passenger safety and the overall efficiency of FSD technology.