Color sanding and buffing are crucial techniques for achieving impeccable fine automobile aesthetics, especially in Mercedes Benz repairs. This meticulous process involves specialized tools and abrasives to shape, smooth, and enhance vehicle body surfaces, ensuring a flawless finish that meets high auto body services standards. In today's competitive auto repair industry, multi-shop coordination is vital for consistent outcomes, with shops pooling expertise and resources to offer comprehensive services including dent removal while maintaining intricate details during color sanding and buffing. Professional technicians prioritize consistent preparation, using appropriate sandpaper and precise techniques, along with top-tier abrasives and machinery for superior results. Effective communication and standardized procedures ensure accurate tracking and final restoration quality, enhancing customer satisfaction and preserving original aesthetics.

“In the realm of multi-shop repair coordination, color sanding and buffing emerge as indispensable techniques for achieving seamless integration and high-quality finishes. This article delves into the intricate world of these processes, offering a comprehensive guide on understanding color sanding and buffing techniques. We explore the pivotal role of multi-shop collaboration and uncover best practices to ensure consistent, exceptional results across diverse repair scenarios. By mastering these skills, professionals can elevate their work, creating lasting, visually appealing repairs.”

- Understanding Color Sanding and Buffing Techniques

- The Role of Multi-Shop Repair Coordination

- Best Practices for Seamless Integration and High-Quality Results

Understanding Color Sanding and Buffing Techniques

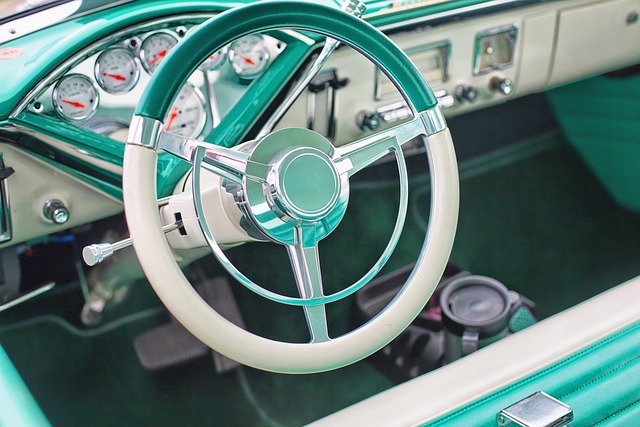

Color sanding and buffing are essential techniques within the multi-shop repair coordination process, particularly for fine automobile aesthetics like those found in Mercedes Benz repairs. This meticulous approach involves using specialized tools and abrasives to shape, smooth, and enhance the surface of vehicle bodies, ensuring a flawless finish that matches the auto body services’ highest standards.

The process starts with color sanding, where coarse-to-fine grits of sandpaper are used to remove imperfections and achieve a uniform base. This step is crucial for preparing the surface before applying auto painting. Once the area is meticulously sanded, buffing comes into play. Buffing utilizes spinning wheels or pads with compounds to polish the surface, creating a smooth, glossy finish that not only enhances visual appeal but also ensures longevity in auto body services. The art of color sanding and buffing requires skill and precision, especially when dealing with intricate details and curves common in modern vehicle designs.

The Role of Multi-Shop Repair Coordination

In today’s competitive auto repair industry, multi-shop repair coordination plays a pivotal role in ensuring high-quality, consistent outcomes for vehicle restoration and customization projects that involve intricate processes like color sanding and buffing. This collaborative approach allows specialized shops to pool their expertise, resources, and advanced equipment, facilitating seamless workflows and faster turnaround times. By coordinating efforts, these shops can offer comprehensive auto repair services, including dent removal and car dent repair, while maintaining meticulous attention to detail during the color sanding and buffing phases.

Multi-shop coordination facilitates a streamlined exchange of knowledge, ensuring that the latest techniques and technologies are implemented across different stages of repair. This cohesion in process and quality control is particularly beneficial for complex restoration projects, where precise color matching and seamless finishes demand utmost precision. Through this collaborative strategy, auto body shops can enhance their capabilities, meet client expectations, and ultimately drive customer satisfaction in the ever-demanding market of car dent repair and customization.

Best Practices for Seamless Integration and High-Quality Results

Achieving seamless integration and high-quality results in color sanding and buffing is paramount in multi-shop repair coordination. Professional technicians understand that consistent preparation and careful application are key. This involves meticulous surface cleaning, thorough sandpaper selection based on material type and damage severity, and precise sanding techniques to ensure an even base for buffering. High-quality abrasives and buffing compounds are essential, as well as the use of appropriate machinery designed for efficient and uniform treatment across all panels.

Effective communication and coordination among repair shops are also vital. Standardized procedures and clear documentation ensure that each stage of the process is accurately tracked and reflected in the final restoration. By adhering to these best practices, automotive body shops can deliver superior results in vehicle collision repair, enhancing customer satisfaction and maintaining the vehicle’s original aesthetics through meticulous color sanding and buffing techniques.

Color sanding and buffing are essential techniques in multi-shop repair coordination, ensuring seamless integration and high-quality results. By understanding these methods and their application, professionals can achieve consistent finishes, enhancing the overall aesthetics of repaired surfaces. Multi-shop collaboration is key to success, with best practices guaranteeing a smooth workflow and exceptional customer satisfaction. This coordinated approach to color sanding and buffing truly revolutionizes the repair industry.