Tesla prioritizes safety throughout its factories through Tesla factory specifications, rigorous protocols ensuring high-voltage compliance during production. Automated systems, advanced monitoring, and protective shielding minimize human interaction with hazardous components, maintaining vehicle integrity and employee well-being. Continuous refinement of these specifications, combined with cutting-edge technologies and comprehensive training, makes Tesla a leader in electric vehicle manufacturing, offering superior safety, reliability, and peace of mind for every vehicle produced.

Tesla’s commitment to high-voltage safety is evident through its stringent factory specifications, ensuring every vehicle produced meets rigorous industry standards. This article explores Tesla’s robust safety measures, delving into the key components and systems designed to protect workers and future drivers. We’ll navigate the regulatory compliance landscape, highlighting ongoing improvements at Tesla factories, as the company continues to revolutionize both electric vehicles and manufacturing practices.

- Understanding Tesla's Factory Safety Standards

- Key Components and Systems for High-Voltage Safety

- Regulatory Compliance and Ongoing Improvements at Tesla Factories

Understanding Tesla's Factory Safety Standards

Tesla’s commitment to safety extends far beyond its vehicles; it begins with rigorous factory specifications designed to ensure high-voltage safety compliance throughout every stage of production. These standards are a cornerstone of Tesla’s mission, prioritizing not only the integrity of their electric vehicles but also the well-being of employees working within their factories.

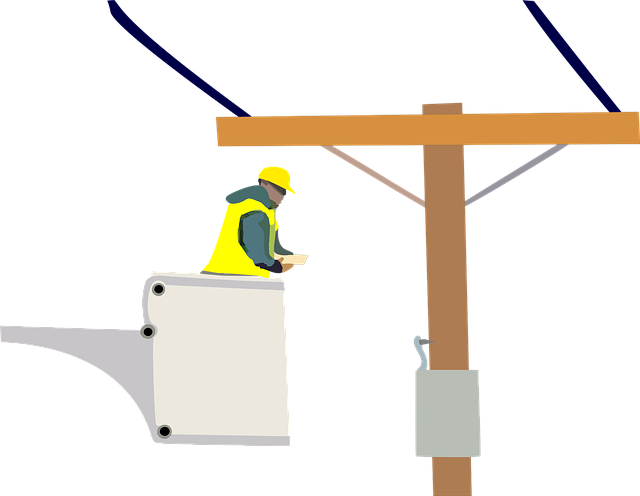

The company’s approach involves implementing stringent protocols for equipment handling, energy storage management, and automated systems to minimize human interaction with high-voltage components. Furthermore, Tesla’s factories are equipped with advanced safety features, including sophisticated monitoring systems that detect any anomalies or potential risks associated with high-voltage operations. By adhering to these Tesla factory specifications, the company ensures a robust safety framework, fostering an environment where cutting-edge auto body painting and collision center services can flourish without compromising on safety measures.

Key Components and Systems for High-Voltage Safety

The Tesla factory specifications prioritize safety when designing high-voltage systems. Key components include robust insulation, protective shielding, and precise grounding mechanisms. These measures safeguard against electrical faults and short circuits, which could lead to hazardous situations. Advanced sensors and monitoring systems continuously evaluate voltage levels, current flows, and potential risks, ensuring immediate responses to any anomalies.

Additionally, Tesla’s factory-standard procedures encompass rigorous testing protocols for every component and system involved in high-voltage operations. This meticulous approach ensures that every vehicle produced adheres to stringent safety standards, mirroring the quality of a well-maintained auto body repair shop or even a specialized bumper repair service. Such comprehensive measures are integral to the overall reliability and peace of mind associated with Tesla vehicles.

Regulatory Compliance and Ongoing Improvements at Tesla Factories

Tesla factories are renowned for their commitment to high-voltage safety compliance, as mandated by stringent regulatory standards. The company’s relentless pursuit of excellence is reflected in its ongoing efforts to enhance and refine Tesla factory specifications, ensuring every vehicle produced meets or exceeds industry safety benchmarks. Through rigorous testing and implementation of cutting-edge technologies, Tesla continues to set the bar for electric vehicle (EV) manufacturing.

Regulatory compliance is not a one-time achievement but an ongoing process at Tesla factories. The company embraces continuous improvement, staying abreast of evolving regulations and industry best practices. This dedication translates into enhanced safety features in every new model, including advanced battery systems and sophisticated safety protocols. Moreover, Tesla’s focus on employee training and state-of-the-art facilities guarantees that car repair services and auto glass repair procedures adhere to the highest standards, contributing to the overall safety and reliability of their vehicles.

Tesla’s commitment to high-voltage safety is evident through its stringent factory specifications, which encompass a robust understanding of key components and systems. By adhering to these rigorous standards and continuously improving their regulatory compliance, Tesla ensures that their electric vehicles not only meet but exceed industry safety benchmarks. The ongoing evolution of their factory safety protocols positions Tesla as a leader in the global shift towards sustainable transportation, instilling confidence in both consumers and the automotive industry at large.