Mercedes EQ electric vehicles' high-voltage (HV) systems necessitate specialized care during any collision or repair due to their dangerous operating voltages up to 800 volts. Trained auto frame repair specialists in body shops specializing in Mercedes EQ EV repair utilize advanced diagnostic tools and strict protocols, including proper disposal of damaged components, to ensure safe interaction with these systems. They competently handle HV repairs while providing top-notch services for overall vehicle restoration, such as structural repairs and refinishing, mitigating risks from electrical shocks and short circuits.

In today’s shift towards electrification, understanding high voltage (HV) safety in Mercedes EQ electric vehicle (EV) repairs is paramount. Unlike traditional collisions, hybrid accidents pose unique risks due to the intricate HV systems integrated into these vehicles. This article delves into the intricacies of these systems, explores potential hazards in hybrid collision scenarios, and provides a comprehensive guide to safe EV/HV repair for Mercedes EQ models, emphasizing best practices and specialized protocols crucial for mastering this complex task.

- High Voltage Systems in Mercedes EQ Vehicles

- – Overview of high voltage (HV) components in the Mercedes EQ electric vehicle (EV)

- – Important safety considerations unique to HV systems

High Voltage Systems in Mercedes EQ Vehicles

Mercedes EQ electric vehicles are equipped with high-voltage systems that require specialized care and knowledge during any type of collision or repair. These systems, designed to power the vehicle’s electric motor and other components, operate at voltages that can pose significant risks if not handled correctly. In the event of a hybrid collision, auto frame repair specialists must be prepared to navigate this delicate balance between high-voltage safety and structural integrity restoration.

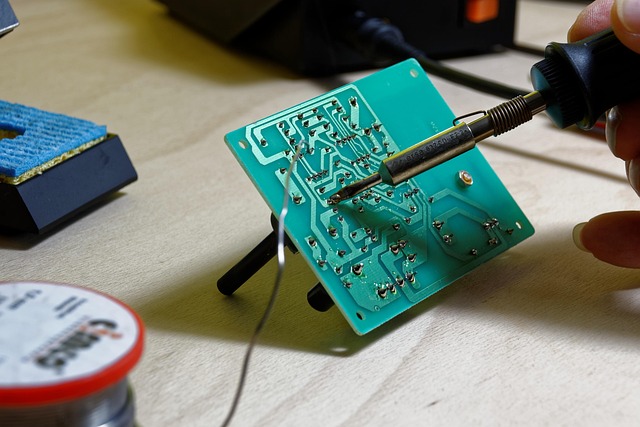

Automotive body shops specializing in Mercedes EQ electric vehicle repair are trained to manage these systems with utmost care. They employ advanced diagnostic tools and safety protocols to assess and mitigate risks associated with high voltage. This includes proper disposal of damaged components, use of insulated tools, and adherence to strict guidelines to ensure the safety of both technicians and customers. An experienced auto repair shop equipped with the right resources can effectively handle these systems while also providing top-notch services for overall vehicle restoration, including structural repairs and refinishing.

– Overview of high voltage (HV) components in the Mercedes EQ electric vehicle (EV)

The Mercedes EQ electric vehicle (EV) is equipped with high-voltage (HV) components that power its electric motor and associated systems. These HV parts, including batteries, inverters, and motor controllers, operate at voltages ranging from 400 to 800 volts, significantly higher than conventional internal combustion engine vehicles. Understanding the location and function of these components is crucial for safe Mercedes EQ electric vehicle repair and maintenance.

Specialized training and knowledge are required to service HV systems due to their high energy levels and potential hazards. For instance, while dent removal or auto body painting may be standard procedures in regular vehicle maintenance, these tasks become more complex with EV repairs, especially when dealing with HV components. Skilled technicians must adhere to strict safety protocols to prevent electrical shocks, short circuits, or other dangerous events during Mercedes Benz repair processes involving high voltage systems.

– Important safety considerations unique to HV systems

When it comes to high voltage (HV) systems, unique safety considerations come into play, especially in the context of hybrid collisions involving electric vehicles like the Mercedes EQ. Unlike conventional internal combustion engines, HV components require specialized handling and repair techniques due to their potential for electrical hazards. These include risks associated with high-energy arcs, sparks, or short circuits that can occur during accidents.

For instance, a collision repair shop specializing in Mercedes EQ electric vehicle repair must be equipped to handle the safe discharge of HV batteries and systems. Proper protocols and training are essential to ensure technicians can effectively navigate these intricate systems without exposing themselves or others to dangerous electrical currents. This specialized knowledge is crucial for effective vehicle repair services, minimizing risks, and ensuring the safety of everyone involved in the auto bodywork process.

In understanding high voltage safety in hybrid collisions, especially within the context of the Mercedes EQ electric vehicle repair, it’s clear that specialized knowledge and stringent safety protocols are paramount. As these vehicles incorporate advanced high voltage systems, proper training and equipment are crucial for safe disassembly and repair. By adhering to best practices, technicians can ensure the well-being of both workers and end users, ultimately contributing to the reliability and longevity of Mercedes EQ electric vehicles.