Side-impact collisions present unique challenges for auto body structural repair, requiring skilled technicians to address complex damage patterns including misalignment, bent panels, and damaged frameworks. The meticulous process involves thorough inspection, precise alignment, structural reinforcement, and complementary services like car paint repair. Modern technologies like CAD, 3D printing, and innovative materials enhance the efficiency and accuracy of repairs, while minimizing environmental impact through techniques like paintless dent repair (PDR). Ultimately, effective auto body structural repair restores vehicles to pre-accident condition, ensuring safety and structural integrity.

In today’s world, understanding auto body structural repair, especially for side-impact collisions, is paramount. This critical aspect of automotive maintenance ensures vehicles return to safe operating conditions post-crash. Side impacts pose unique challenges due to concentrated force and potential vulnerability of smaller vehicle areas. This article delves into these complexities, outlining the meticulous process of auto body structural repair, from assessment to advanced technologies employed in modern repairs. Learn how these innovations enhance safety and restoration.

- Understanding Side-Impact Collisions and Their Unique Challenges

- The Process of Auto Body Structural Repair: Step by Step

- Advanced Techniques and Technologies in Modern Structural Repairs

Understanding Side-Impact Collisions and Their Unique Challenges

Side-impact collisions represent a unique challenge for auto body structural repair professionals. These types of accidents often occur when one vehicle hits another at an angle, resulting in complex damage patterns. Unlike frontal or rear-end crashes, side impacts can cause misalignment, bent panels, and even damaged frameworks, requiring precise expertise to restore the vehicle’s structural integrity.

Understanding the specific challenges posed by these incidents is crucial for any auto collision center. The impact force is often unevenly distributed, leading to localized damage that may not be immediately apparent. This complexity necessitates a meticulous approach to repair, involving not just body panel replacement but also precise alignment and structural reinforcement. Services like car paint repair and tire services might also be required as part of the overall restoration process, ensuring the vehicle not only looks its best but also drives safely and smoothly after the auto body structural repair is completed.

The Process of Auto Body Structural Repair: Step by Step

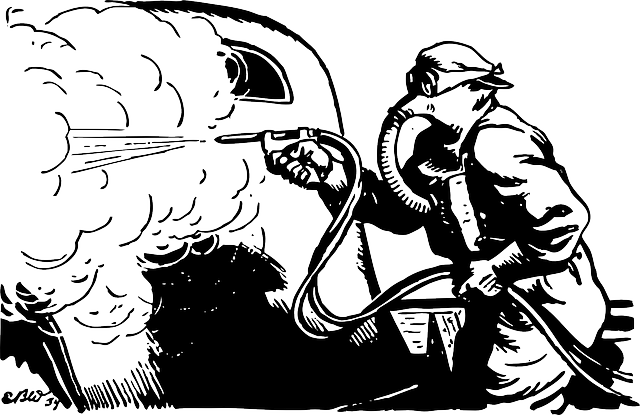

Auto Body Structural Repair for side-impact collisions involves a meticulous process designed to restore vehicles to their pre-accident condition. It’s crucial for ensuring safety and structural integrity, minimizing damage to critical components like frames, panels, and suspension systems. The procedure begins with a thorough inspection to identify impact zones and assess the extent of damage. Next, damaged parts are carefully removed, using specialized tools to separate them from the vehicle without causing further harm.

Once the affected areas are exposed, skilled technicians employ precision techniques for auto body structural repair. This may involve straightening bent frames, replacing crushed panels, and realigning misaligned components. Advanced equipment like hydraulic presses and computer-aided measurement tools assist in achieving accurate restoration. After ensuring proper alignment and fit, the repair progresses to the secondary stage: preparing the surface for auto body painting. This includes sanding, priming, and applying layers of paint, meticulously matching the original finish for a seamless, visible-free outcome that restores both aesthetics and safety standards.

Advanced Techniques and Technologies in Modern Structural Repairs

In the realm of auto body structural repair, modern technologies and advanced techniques are revolutionizing the way we address side-impact collisions. Innovations such as computer-aided design (CAD) and three-dimensional (3D) printing enable precise measurements and customized repairs, ensuring that vehicles return to their pre-accident condition. These digital tools allow for a more efficient and accurate assessment of damage, facilitating faster turnaround times without compromising quality.

Moreover, advancements in materials science have led to lighter and stronger components, enhancing safety standards while reducing repair costs. Technologies like paintless dent repair (PDR) also contribute significantly to the modern auto body services landscape. PDR methods use specialized tools to remove dents from the exterior of a vehicle without damaging the paintwork, resulting in less waste and a more environmentally friendly process. These innovations collectively underscore the ongoing evolution of auto body structural repair, catering to the ever-changing demands of both industry professionals and car owners.

In conclusion, mastering auto body structural repair, particularly for side-impact collisions, involves a deep understanding of these unique challenges. By employing advanced techniques and technologies, such as precision measurement tools and specialized welding methods, professionals can ensure vehicles return to their pre-collision state. This process not only restores safety but also maintains the vehicle’s aesthetic integrity, showcasing the importance of expert auto body structural repair in today’s automotive industry.