Selecting specialized PDR (Paintless Dent Repair) tools designed for aluminum panels is vital for achieving high-quality, precise repairs. Beginners should avoid generic equipment and opt for dedicated aluminum removal tools to prevent dents and scratches. High-quality tools from reputable manufacturers ensure effective, efficient repairs, minimizing damage and enhancing customer satisfaction. Using the right equipment for PDR on aluminum significantly maintains the original finish, avoids mistakes, reduces repair times, and lowers labor costs.

In today’s automotive landscape, Professional Detaching Repair (PDR) on aluminum panels has become a common practice. However, many mistakes are often made, leading to suboptimal results or even damage. This article explores critical areas where professionals and enthusiasts alike can avoid pitfalls in the PDR process for aluminum panels. By understanding the right tools, effective techniques, and unique material properties of aluminum, you can master PDR and ensure superior repair outcomes.

- Choosing the Right Tools and Equipment

- – Importance of high-quality tools for accurate measurements and minimal damage

- – Common mistakes related to using inferior equipment and their consequences

Choosing the Right Tools and Equipment

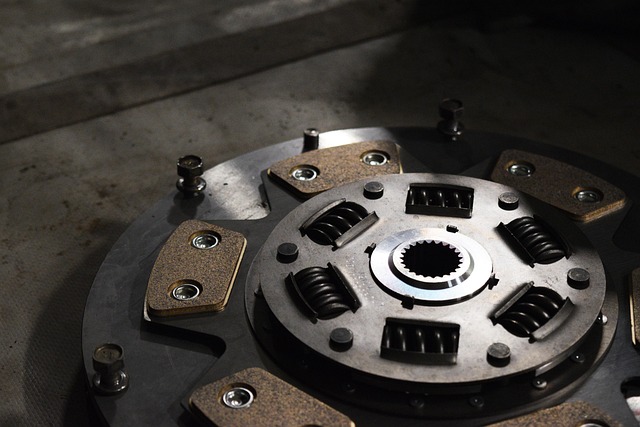

When it comes to PDR for aluminum panels, selecting the appropriate tools and equipment is paramount to achieving flawless results. Many beginners often fall into the trap of using generic tools meant for other material types, which can lead to disappointing outcomes. Aluminum presents unique challenges due to its softness and tendency to dent easily, so specialized tools designed specifically for this metal are crucial. These include dedicated dings and creases removal tools, as well as soft foam pads tailored for aluminum surfaces to prevent marring or scratching.

Investing in high-quality equipment from reputable manufacturers ensures that the PDR process is effective and efficient. The right set of tools enables precise control during the repair, minimizing damage to surrounding areas and maximizing the restoration of the aluminum panel’s original condition. A well-equipped collision repair shop offering tire services can significantly enhance customer satisfaction by delivering top-notch PDR for aluminum panels, setting them apart from their competitors in the market.

– Importance of high-quality tools for accurate measurements and minimal damage

In the realm of PDR for aluminum panels, utilizing high-quality tools is paramount. These tools play a crucial role in achieving precise measurements and minimizing damage during the repair process. When selecting equipment for car dent repair on aluminum bodies, professionals should opt for top-tier instruments designed specifically for this material. Such tools often boast advanced features that enable accurate alignment and gentle manipulation of the panel, ensuring the integrity of the auto body repair services.

High-quality PDR tools can significantly reduce the risk of damaging the panel or leaving unsightly marks. They facilitate cleaner, more precise repairs, leading to better outcomes in auto body repair. By investing in these tools, technicians can enhance their efficiency and skill in handling various car dent repair tasks, ultimately elevating the overall quality of their work across different types of vehicles and panel configurations.

– Common mistakes related to using inferior equipment and their consequences

Using inferior equipment for PDR (Paintless Dent Repair) on aluminum panels is a common mistake that can lead to poor results and even damage to the vehicle’s surface. Low-quality tools may lack the precision and power needed to effectively remove dents, often leaving visible marks or indentations. This not only compromises the aesthetics of the car restoration process but also reflects poorly on the reputation of the car paint services provider.

Consequences of such mistakes include prolonged repair times, increased labor costs, and dissatisfied customers. In the world of vehicle dent repair, using the right equipment is paramount to ensure a smooth, seamless, and long-lasting fix. Proper PDR tools allow for precise control, enabling professionals to perform car restoration with minimal impact on the panel’s original finish, thus delivering top-notch car paint services that meet or exceed customer expectations.

In conclusion, avoiding common mistakes in PDR (Paintless Dent Repair) for aluminum panels begins with investing in high-quality tools. Using proper equipment ensures accurate measurements and minimizes damage, resulting in superior repair outcomes. By understanding the impact of inferior tools and making informed choices, professionals can elevate their work, satisfy customers, and maintain a competitive edge in the PDR industry, specifically for aluminum panel repairs.