The A-pillar, a crucial structural element in vehicles, requires specialized repair due to common issues like accidents, corrosion, or manufacturing defects. Efficient A-pillar repair operations depend on strategic labor scheduling, digital tools for real-time adjustments, clear communication channels, and dedicated personnel. By integrating these practices, collision centers and car body shops can enhance customer satisfaction, optimize operational efficiency, and ensure high-quality A-pillar repair outcomes.

In today’s automotive landscape, efficient A-pillar repair is paramount for maintaining vehicle safety and aesthetics. This article delves into the intricacies of A-pillar repair, exploring its essential components and common issues. We present effective labor scheduling strategies to streamline operations, ensuring swift and accurate repairs. Additionally, we discuss coordination techniques that optimize A-pillar repair processes, ultimately enhancing customer satisfaction with every service interaction.

- Understanding A-Pillar Repair: Essential Components and Common Issues

- Efficient Labor Scheduling Strategies for Seamless A-Pillar Repair Operations

- Coordination Techniques to Optimize A-Pillar Repair and Enhance Customer Satisfaction

Understanding A-Pillar Repair: Essential Components and Common Issues

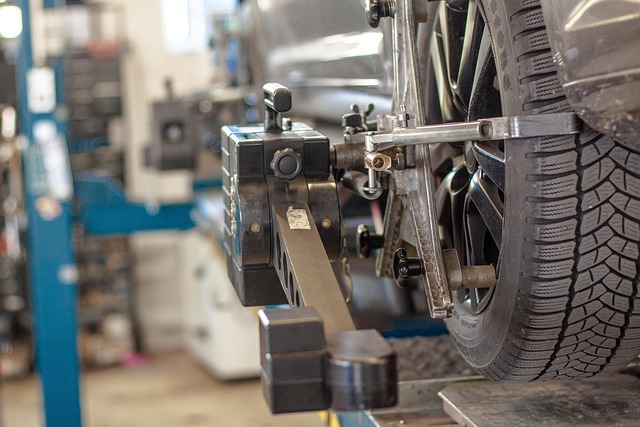

The A-pillar, a structural component in vehicles, connects the roof to the side body panels and is vital for both safety and vehicle integrity. Understanding its complex makeup and potential issues is crucial when it comes to effective repairs. This pillar comprises several key elements: metal frames, reinforcements, and various fixings. Common problems include damage from accidents, corrosion, or manufacturing defects, leading to weaknesses in the structure that can compromise vehicle stability.

Proper A-pillar repair involves skilled technicians who can assess and address these issues. It often requires specialized tools and knowledge to disassemble and replace affected parts without compromising the overall structural integrity. Efficient coordination between body shop services and skilled labor is essential for ensuring accurate and timely repairs, especially when dealing with intricate vehicle paint repair and restoration processes.

Efficient Labor Scheduling Strategies for Seamless A-Pillar Repair Operations

Efficient Labor scheduling is paramount to ensuring seamless A-pillar repair operations. By implementing strategic strategies, automotive service centers can optimize workforce allocation, minimizing downtime and enhancing customer satisfaction. One effective approach involves creating detailed work schedules that align with peak demand periods, allowing for adequate staffing during busy times while preventing overstaffing during lulls. This balance ensures technicians are available when needed, accelerating repair processes like tire services, fender repairs, or car damage repairs.

Additionally, leveraging digital scheduling tools can streamline the process, enabling real-time adjustments based on changing circumstances. These systems facilitate clear communication among team members and improve overall coordination. By combining these tactics, service centers can maintain a high level of efficiency in A-pillar repair operations, ensuring cars are back on the road safely and promptly.

Coordination Techniques to Optimize A-Pillar Repair and Enhance Customer Satisfaction

In the realm of automotive repairs, especially concerning A-pillar repair, efficient coordination is key to enhancing customer satisfaction and streamlining operations within a collision center or car body shop services. Techniques such as integrated digital scheduling software can significantly optimize the process. This technology allows for real-time updates, ensuring that all team members, from estimators to technicians, are on the same page regarding repair priorities. By seamlessly integrating this system with existing workflows, shops can minimize delays and maximize productivity.

Moreover, effective coordination involves clear communication channels and well-defined roles. Assigning dedicated personnel for A-pillar repairs ensures specialized care, leading to higher quality outcomes. Regular staff meetings and briefings can further enhance coordination by addressing any challenges promptly. Ultimately, these collaborative efforts translate into faster turnaround times, satisfied customers, and a harmonious work environment in the collision center or car body restoration facility.

A-pillar repair is a complex process that requires meticulous planning and coordination. By implementing efficient labor scheduling strategies and utilizing effective coordination techniques, auto shops can streamline their A-pillar repair operations, reduce downtime for customers, and enhance overall satisfaction. These practices ensure that skilled technicians are allocated appropriately, parts are readily available, and communication remains clear throughout the repair process, ultimately contributing to a successful and positive customer experience.