The Tesla Measure System is an innovative solution for vehicle measurement and repair, leveraging advanced sensor tech and AI for unprecedented accuracy and efficiency. It automates processes, reduces human error, and enhances standards in collision centers and fender repair shops through precise data, 3D models of damage, and factory-like restoration outcomes. Despite the allure of its cutting-edge features, traditional measuring tools remain valuable for specific tasks, combining decades of refinement with reliability and accuracy in critical areas like auto body painting and complex engineering projects.

In the realm of measurement, a paradigm shift is underway with the advent of the Tesla Measure System. This innovative approach promises to revolutionize traditional measuring tools by offering unprecedented accuracy and efficiency. This article delves into this new system, exploring its advantages over conventional methods and highlighting specific use cases where it shines. We also examine the challenges and limitations, revealing that traditional tools still have their place in certain scenarios.

- Understanding the Tesla Measure System: A New Paradigm in Measurement

- Advantages of Tesla Measure System Over Traditional Tools

- Challenges and Limitations: Where Traditional Measuring Tools Still Have Their Place

Understanding the Tesla Measure System: A New Paradigm in Measurement

The Tesla Measure System represents a revolutionary paradigm shift in the field of measurement, particularly within the automotive industry. This cutting-edge technology is transforming the way we assess and repair vehicles, offering unprecedented precision and efficiency. Unlike traditional measuring tools that often rely on manual calibration and human interpretation, the Tesla Measure System leverages advanced sensor technology and artificial intelligence to provide exacting data. It can swiftly scan and analyze a vehicle’s body, including intricate details like panel gaps, angles, and curves, with remarkable accuracy.

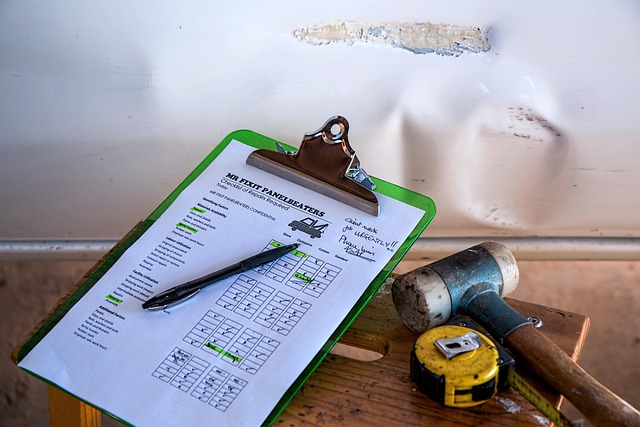

This innovative system is particularly beneficial in collision centers and fender repair shops. By automating the measurement process, it streamlines workflows, reduces human error, and expedites repairs. Moreover, its ability to capture detailed 3D models of vehicle damage enables more effective dent removal and precise restoration, ensuring a factory-like finish. The Tesla Measure System is not merely a tool; it’s a game-changer that redefines the standards of quality and efficiency in the automotive aftercare sector.

Advantages of Tesla Measure System Over Traditional Tools

The Tesla Measure System offers several advantages over traditional measuring tools when it comes to tasks like auto body repair and vehicle restoration. One key benefit is its precision and accuracy, enabled by advanced technologies such as laser scanning and 3D imaging. These capabilities allow for detailed measurements of vehicle surfaces, ensuring minimal errors in dent removal or structural adjustments during the repair process.

Additionally, the Tesla Measure System streamlines workflows significantly. By providing real-time data and digital records, it reduces manual measurement and documentation tasks, saving time and minimizing opportunities for human error. This streamlined approach is particularly beneficial for folks engaged in vehicle restoration projects, enabling them to focus more on intricate work like detailing and finishing, while maintaining high standards of precision in structural integrity.

Challenges and Limitations: Where Traditional Measuring Tools Still Have Their Place

While the Tesla measure system offers numerous advantages, it’s important to acknowledge that traditional measuring tools still hold their ground in specific scenarios, especially in the domain of automotive collision repair and vehicle collision repair. These conventional tools have been refined over decades, providing precise measurements for critical tasks like auto body painting and complex engineering projects.

Their reliability and accuracy in certain situations cannot be overlooked. For instance, when dealing with intricate metalwork or fine adjustments during auto body painting, traditional calipers, tape measures, and angle gauges offer the precision required. Moreover, many seasoned professionals in vehicle collision repair prefer these tools due to their familiarity and the ability to quickly interpret results without relying on advanced technology.

The Tesla Measure System represents a significant shift in how we perceive measurement, offering unparalleled precision and efficiency compared to traditional tools. Its advantages are compelling, particularly in industries demanding accurate, real-time data. However, it’s crucial to acknowledge that traditional measuring tools still hold value for certain tasks due to their accessibility, cost-effectiveness, and specialized applications. Striking a balance between the two systems can lead to optimal measurement solutions, ensuring professionals leverage the best tools for each unique situation.