The evolution of hatchback design, driven by safety standards and advanced materials, has transformed hatchback collision repair into a specialized field requiring innovative techniques like robotic welding and precision measurement. This revolution has streamlined processes, reduced turnaround times, and improved quality, setting new industry benchmarks while fostering competition and driving down costs for consumers. Advanced methods such as frame straightening enhance damage mitigation, preserving structural integrity and visual appeal unique to hatchbacks, ultimately enhancing road safety and the overall driving experience.

Hatchback vehicles have evolved significantly over the years, transforming not just their design but also safety standards. This shift has had a profound impact on the market, particularly in hatchback collision repair. As hatchback designs become more complex, so too have the repair processes and technologies required to address them. This article explores the hatchback collision repair landscape, delving into the evolution of design, the influence on safety standards, and the subsequent transformations in industry practices, ultimately highlighting benefits for both consumers and businesses.

- The Evolution of Hatchback Design and Safety Standards

- Impact on Collision Repair Processes and Technologies

- Market Transformation: Benefits for Consumers and Businesses

The Evolution of Hatchback Design and Safety Standards

The evolution of hatchback design has gone hand-in-hand with advancements in safety standards. In the past, hatchbacks were primarily known for their compact size and practicality, often sacrificing some structural integrity to achieve better fuel efficiency and maneuverability. However, as consumer demand for safer vehicles grew, so did the emphasis on robust construction. Modern hatchbacks now boast sophisticated crash-test ratings, thanks to stringent regulations and innovative engineering. Advanced materials like high-strength steel and lightweight composites are seamlessly integrated into car body shop processes, enhancing both structural integrity and fuel efficiency.

This shift has significantly impacted the automotive industry, particularly in hatchback collision repair. Car body shops have had to adapt their auto body services to cater to these new designs. With more complex panel arrangements and an increased focus on precision during repairs, technicians require specialized skills and training. This evolution underscores the constant interplay between vehicle aesthetics and safety, pushing car body shop professionals to stay at the forefront of repair technology and techniques.

Impact on Collision Repair Processes and Technologies

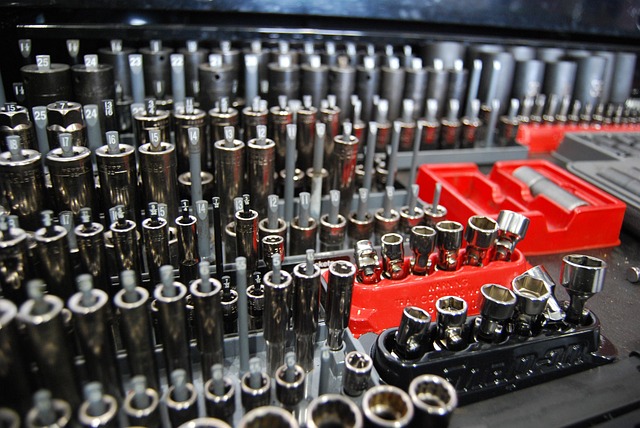

The advent of hatchback collision repair has significantly transformed traditional car repair processes and technologies. With their unique design, hatchbacks present distinct challenges compared to other vehicle types, prompting the development of specialized tools and techniques. Mechanics now employ advanced equipment, such as robotic welding systems and precision measurement tools, to ensure accurate repairs that maintain the structural integrity and aesthetic appeal of these vehicles.

This evolution has not only streamlined the repair process but also elevated the standard for car repair services. Techniques like panel replacement, which involves swapping out damaged parts with new ones, have become more efficient and precise. Similarly, technologies focused on fender repair and bumper repair have been refined, allowing for quicker turnaround times and higher quality outcomes. The result is a market where hatchback collision repair sets new benchmarks for both functionality and aesthetics.

Market Transformation: Benefits for Consumers and Businesses

The transformation of hatchback collision repair has brought about significant changes in the automotive industry, offering a multitude of benefits for both consumers and businesses alike. This innovative approach to vehicle bodywork repair has revolutionized traditional methods, ensuring faster turnaround times and superior quality outcomes. With advanced techniques like frame straightening, auto repair services can now effectively mitigate damage, preserving the structural integrity of hatchbacks while reducing costs for owners.

For consumers, this means easier access to reliable and affordable repair solutions. The market’s shift towards hatchback collision repair has fostered competition among service providers, driving down prices and encouraging businesses to offer more comprehensive packages. As a result, vehicle owners can expect top-notch auto repair services tailored to their specific needs, ultimately enhancing road safety and the overall driving experience.

The evolution of hatchback design, driven by stringent safety standards, has significantly reshaped the market for hatchback collision repair. Advancements in materials, engineering, and technology have streamlined repair processes, enhancing efficiency and quality. This transformation benefits both consumers and businesses: repairs are faster, more affordable, and environmentally friendly, while specialized knowledge and tools ensure optimal vehicle restoration. The modern approach to hatchback collision repair sets new benchmarks for the industry, promising better outcomes and a smoother experience for all involved.