North side collision repair excels through stringent Quality Control (QC) processes, ensuring structural integrity, paint quality, and cosmetic restoration meet high standards. This competitive market requires advanced techniques, continuous staff training, and equipment upgrades to attract clients and build trust. Rigorous assessment, precise disassembly, standardized procedures, and advanced technologies like CAD systems ensure consistent, exceptional results across all repair stages.

In the competitive landscape of automotive services, maintaining high standards is paramount, especially in north side collision repair. This article explores the crucial aspect of quality control and its impact on ensuring top-notch repairs. We delve into the significance of setting specific standards for local shops, emphasizing a comprehensive approach to consistency. By understanding the fundamentals of quality control, north side collision repair businesses can enhance customer satisfaction and establish themselves as trusted, reliable service providers.

- Understanding Quality Control in Collision Repair

- Setting Standards for North Side Shops

- Maintaining Consistency: A Comprehensive Approach

Understanding Quality Control in Collision Repair

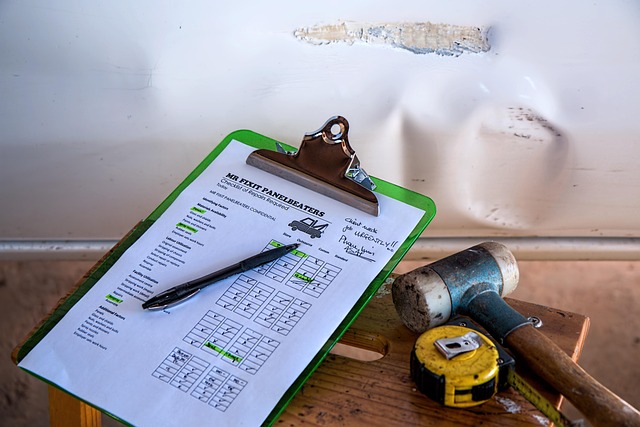

Quality Control (QC) is a vital process in the north side collision repair industry, ensuring that each vehicle undergoes rigorous inspection and meets stringent standards before it leaves the workshop. It’s more than just checking for visible damage; it involves a comprehensive assessment of every aspect of the repair, from structural integrity to paint quality and cosmetic restoration. The primary goal is to guarantee that the car is not only safe to drive but also matches its pre-accident condition as closely as possible.

In collision repair, QC includes meticulous procedures such as measuring and comparing parts, checking for proper alignment, and verifying that dent removal techniques have been applied accurately. Skilled technicians inspect every detail, from the accuracy of panel fitting to the quality of paint finish, using advanced tools and their expert knowledge. This process is crucial in maintaining high standards, ensuring customer satisfaction, and building trust in north side collision repair services.

Setting Standards for North Side Shops

In the competitive landscape of north side collision repair services, setting and maintaining high standards is paramount for customer satisfaction and business success. Shops on the north side must strive to meet or exceed industry benchmarks in various aspects of their operations, from car body repair techniques to paintless dent repair technologies. This commitment ensures that vehicles leave the workshop not just fixed but also restored to their pre-accident condition, or even better.

The north side collision repair scene benefits from a diverse range of services, including top-notch auto detailing. To stay ahead, local shops need to invest in continuous training for their staff and equipment upgrades to deliver cutting-edge solutions. By adopting these practices, north side collision repair professionals can stand out, attract more clients, and foster long-term trust with their customers.

Maintaining Consistency: A Comprehensive Approach

In the realm of north side collision repair, maintaining consistency is paramount to ensuring high-quality outcomes. A comprehensive approach involves integrating rigorous standards across every stage of the repair process, from initial assessment to final inspection. This includes meticulous attention to detail during disassembly and reassembly, utilizing specialized tools and techniques tailored for diverse vehicle models. By upholding stringent protocols, north side collision repair shops can deliver repairs that match or exceed the original factory specifications.

This consistency is further bolstered through comprehensive training programs for staff and technicians, fostering a culture of excellence. Standardized procedures for auto body painting and car scratch repair ensure uniform results, minimizing variations that could compromise the final aesthetic. The integration of advanced technologies, such as computer-aided design (CAD) systems and robotic paint applications, plays a pivotal role in achieving this consistency, enabling precise measurements and consistent application across all repairs, whether simple or complex.

In conclusion, implementing robust quality control standards is paramount for maintaining excellence in North Side collision repair. By setting clear guidelines and fostering a culture of consistency, local shops can ensure their work meets or exceeds industry benchmarks. This comprehensive approach not only safeguards customer satisfaction but also positions these businesses as leaders in the competitive north side collision repair landscape.