Collision repair benchmarking is a strategic process that leverages data-driven comparisons to drive quality improvements across the industry. By evaluating performance metrics like auto frame repair times, shops can identify best practices and areas for enhancement, ultimately leading to faster turnaround times, efficient workflows, and superior vehicle restoration outcomes. This continuous improvement benefits both businesses and consumers by ensuring every repair job meets or exceeds customer expectations.

In today’s competitive automotive industry, collision repair benchmarking is a game-changer. This powerful strategy equips repair shops with the tools to set industry standards and transform customer experiences. By comparing performance against peers, benchmarks drive operational efficiency, quality enhancement, and innovative practices.

This article explores real-world examples of success from collision repair benchmarking efforts, highlighting how:

Shops can boost productivity and customer satisfaction through targeted improvements.

Benchmarking fosters innovation and significantly reduces critical repair times.

* Key performance indicators (KPIs) and advanced data tools are instrumental in driving continuous improvement beyond initial benchmarks.

- Setting the Standard: How Benchmarking Transforms Collision Repair Quality

- – Defining collision repair benchmarking and its purpose

- – Benefits of implementing benchmarking practices

Setting the Standard: How Benchmarking Transforms Collision Repair Quality

Collision repair benchmarking sets a new standard for quality in the industry. By comparing performance metrics across different collision repair shops, professionals can identify areas of excellence and pinpoint areas that need improvement. This data-driven approach ensures that each repair job meets or exceeds customer expectations. Through benchmarking, shops can access best practices from peers, leading to more accurate estimates, efficient workflows, and superior vehicle restoration outcomes.

For instance, a comprehensive benchmarking study might compare the time taken for auto frame repair across various facilities. The results could highlight an outlier—a shop consistently completing repairs faster with minimal compromise on quality. This knowledge allows other collision centers to adopt similar techniques, potentially reducing turnaround times and customer wait periods. Ultimately, benchmarking fosters a culture of continuous improvement in collision repair, benefiting both businesses and consumers alike through enhanced auto body restoration services.

– Defining collision repair benchmarking and its purpose

– Benefits of implementing benchmarking practices

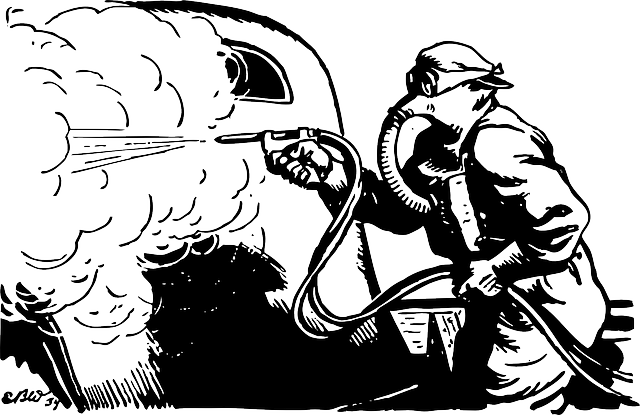

Collision repair benchmarking is a powerful strategy that offers numerous advantages for garages and repair centers. By comparing their processes and outcomes to industry standards and best practices, businesses can identify areas for improvement and drive excellence in their services. This practice allows them to stay ahead of the competition by consistently delivering high-quality repairs, ensuring customer satisfaction, and optimizing operational efficiency.

Implementing benchmarking practices enables specialists in fender repair and vehicle collision repair to refine techniques, especially in complex tasks like frame straightening. It encourages a culture of continuous learning and improvement, where garages can benchmark not only their overall performance but also specific services such as paint jobs and mechanical repairs. This targeted approach leads to better-quality workmanship, reduced repair times, and ultimately, enhanced customer retention.

Collision repair benchmarking is not just a concept—it’s a proven strategy with real-world success stories. By setting industry standards, benchmarking empowers shops to consistently deliver high-quality repairs, enhance customer satisfaction, and stay ahead of the competition. Through data-driven insights, technicians can refine their processes, invest in the right tools, and maintain a reputation for excellence. This holistic approach ensures that collision repair facilities aren’t just meeting expectations but exceeding them, ultimately fostering a culture of continuous improvement within the industry.