Induction heating systems offer a clean, efficient alternative to traditional metalworking methods in repair environments. By generating heat through eddy currents, these systems minimize energy waste and damage, ideal for vehicle restoration. They provide precise temperature control, reduce environmental pollution by eliminating harmful emissions, and are versatile across industries, from auto repairs to electronics manufacturing.

Induction heating systems are transforming repair environments by offering efficient, clean, and versatile solutions. This advanced technology excels in precisely heating metal, reducing energy wastage and associated environmental impacts. By eliminating harmful emissions and pollution risks commonly linked to traditional heating methods, induction systems contribute to a greener landscape. From automotive repairs to electronics assembly, these systems provide a sustainable alternative, ensuring a cleaner, more eco-conscious repair process.

- Efficient Metal Heating: Induction Systems' Role

- Environmental Benefits: Reducing Pollution Risks

- Versatile Applications: From Auto Repairs to Electronics

Efficient Metal Heating: Induction Systems' Role

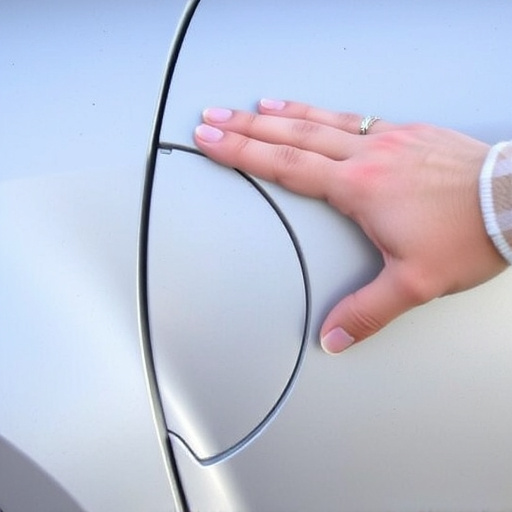

Induction heating systems have revolutionized the way we approach metalworking, particularly in clean repair environments. Unlike traditional methods that rely on open flames or resistive heating, induction systems offer a more efficient and precise means of heating metals. This is especially beneficial in vehicle restoration and frame straightening processes, where maintaining minimal heat input to surrounding materials is crucial.

These systems work by inducing eddy currents in the metal being heated, which in turn generates heat through resistance. This targeted approach ensures that only the necessary areas are warmed, minimizing energy waste and reducing the risk of damaging adjacent components commonly found in vehicle bodywork. As a result, induction heating systems contribute significantly to cleaner, more controlled repair environments, allowing for high-quality work with minimal environmental impact.

Environmental Benefits: Reducing Pollution Risks

Induction heating systems offer significant advantages when it comes to environmental considerations, especially in the context of auto body repairs and automotive restoration. One of the key benefits is their ability to reduce pollution risks associated with traditional heating methods. By using electromagnetic fields to generate heat directly within the material, these systems minimize the release of harmful emissions and volatile organic compounds (VOCs) often found in other repair processes.

This eco-friendly approach is particularly relevant for auto repair shops, as it helps them maintain a clean and healthy work environment while also contributing to a greener planet. With induction heating, there’s no need for toxic chemicals or flammable materials, making it a safer option for both workers and the surrounding community, especially when compared to traditional welding techniques. This shift towards cleaner processes is a step in the right direction for the automotive industry, ensuring that auto body repairs are not just efficient but also environmentally conscious.

Versatile Applications: From Auto Repairs to Electronics

Induction heating systems have proven to be versatile tools with applications spanning a wide range of industries and processes. In the realm of repairs and maintenance, these systems play a significant role in creating cleaner and more efficient work environments. One notable area where induction heating has made its mark is automotive repair. From minor scratch repairs to complex car bodywork services, induction heating offers precise temperature control, enabling technicians to perform intricate modifications without generating harmful emissions or excessive heat that could damage sensitive components.

Moreover, the technology extends beyond auto repairs and finds utility in electronics manufacturing. For instance, during auto glass replacement, induction heating can be employed to fuse new glass panels seamlessly into existing frames, eliminating the need for toxic adhesives. This not only streamlines the process but also contributes to a cleaner, greener repair environment. The adaptability of induction heating systems makes them indispensable tools in modern repair facilities, promoting sustainability and efficiency across various sectors.

Induction heating systems stand out as versatile and efficient solutions for clean repair environments, offering significant advantages in metal heating applications. By reducing pollution risks associated with traditional methods, these systems contribute to a more sustainable approach in various industries, from automotive repairs to electronics manufacturing. Their versatility allows for precise control over heat, making them indispensable tools for achieving high-quality outcomes while minimizing environmental impact.