Defining key metrics like dimensional accuracy and material properties analysis is vital for high-quality automotive repairs. Visual inspections using advanced tools ensure precision in cosmetic repairs, while standardized testing protocols provide consistent, reliable repair quality measurements across various vehicle types, fostering customer confidence in structural integrity.

In the realm of repairs, ensuring structural integrity and cosmetic accuracy is paramount. This comprehensive guide delves into crucial repair quality measurements essential for both structural and cosmetic repairs. We explore defining key metrics for maintaining structural integrity, advanced visual inspection techniques for meticulous cosmetic precision, and standardized testing protocols to assess repairs comprehensively. By implementing these strategies, professionals can enhance repair outcomes, fostering longevity and aesthetic appeal in today’s demanding landscape.

- Defining Key Metrics for Structural Integrity

- Visual Inspection Techniques for Cosmetic Accuracy

- Standardized Testing Protocols for Repairs Assessment

Defining Key Metrics for Structural Integrity

Defining key metrics for structural integrity is a critical step in ensuring high-quality repairs, be it for a car repair shop, collision center, or any facility handling vehicle fixes. These measurements go beyond mere visual assessments and involve precise techniques to gauge the strength and stability of components. One essential metric is dimensional accuracy, which checks if parts are aligned correctly after repairs or adjustments, especially in frame straightening processes.

Another vital measurement is material properties analysis, where the integrity and performance of materials used in repairs are evaluated. This includes tests for tensile strength, corrosion resistance, and ductility to guarantee that the repair matches or surpasses the original vehicle’s structural capabilities. By focusing on these metrics, collision centers can maintain consistent repair quality measurements, ensuring customer safety and satisfaction.

Visual Inspection Techniques for Cosmetic Accuracy

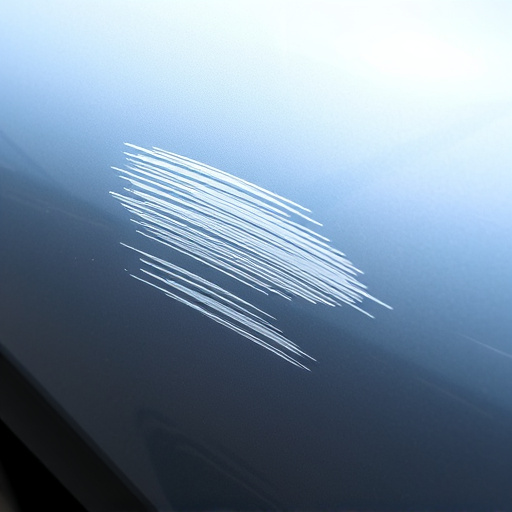

Visual inspection is a critical component of repair quality measurements, especially for cosmetic repairs aiming for precision and accuracy. Skilled technicians utilize various techniques to ensure every detail is considered. This includes a thorough examination with the naked eye, magnifying glasses, and high-resolution cameras to capture even subtle imperfections. By examining the surface, edges, and surrounding areas, they can identify issues like misaligned panels, uneven paint jobs, or hidden damage that might have gone unnoticed.

For instance, in Mercedes Benz repair, where precision is paramount, visual inspection techniques are indispensable. Paintless dent repair (PDR) methods rely heavily on this practice to restore vehicles to their original condition, ensuring no trace of hail damage or other cosmetic imperfections remain. Similarly, when assessing the quality of a hail damage repair, a meticulous visual inspection guarantees that each dent is accurately addressed, resulting in a seamless and flawless finish.

Standardized Testing Protocols for Repairs Assessment

In the pursuit of excellence in vehicle repair, establishing standardized testing protocols is paramount for accurately assessing repair quality measurements. These protocols serve as a benchmark, ensuring that every luxury vehicle repair or even straightforward vehicle dent repair undergoes a meticulous evaluation process. By implementing consistent methods, vehicle body shops can achieve reliable and comparable results. This standardization facilitates a comprehensive understanding of repair effectiveness, enabling professionals to identify potential areas of improvement within the industry.

For instance, when evaluating cosmetic repairs on a vehicle body shop’s fleet, these protocols may include detailed visual inspections, pressure testing for paint jobs, and dimensional analysis to ensure panels align perfectly. Similarly, assessing structural repairs involves load tests and simulations to verify the strength and integrity of components. Such comprehensive testing not only guarantees superior repair quality but also instills confidence in customers who rely on these services for their vehicle’s aesthetic and structural integrity.

By defining key metrics for structural integrity, employing advanced visual inspection techniques, and implementing standardized testing protocols, we can significantly enhance repair quality measurements. These practices ensure both the durability and aesthetic appeal of repairs, fostering a standard of excellence across the industry. Incorporating these strategies into repair processes is vital for maintaining safety, customer satisfaction, and the overall value of assets.