Mercedes Boron steel cutting transforms automotive repairs and industrial applications with its exceptional strength, precision, and durability. This high-performance alloy's strategic composition enhances cutting performance, enabling clean cuts while preserving structural integrity. Specialized tools and meticulous preparation ensure top-notch results for vehicle paint repairs and bodywork, minimizing damage evidence. Its lightweight yet robust nature and superior corrosion resistance revolutionize manufacturing, collision repair, and aerospace industries.

Mercedes boron steel, known for its exceptional hardness and strength, offers unique advantages in cutting applications. This article delves into the precise art of cutting Mercedes boron steel with minimal distortion, exploring its exceptional properties. We’ll uncover specialized techniques employed by professionals and discuss the numerous benefits and diverse industrial applications driven by this innovative material. From precision engineering to advanced manufacturing, understand why Mercedes boron steel cutting is a game-changer in modern industry.

- Understanding Mercedes Boron Steel Properties

- Cutting Techniques for Minimal Distortion

- Advantages and Applications in Industry

Understanding Mercedes Boron Steel Properties

Mercedes Boron steel is a high-strength alloy renowned for its exceptional cutting performance with minimal distortion. This advanced material has gained prominence in the automotive industry, offering a game-changing solution for car damage repair and vehicle paint repair processes. Its unique properties are attributed to the strategic incorporation of boron, which enhances tensile strength and toughness compared to traditional steel grades.

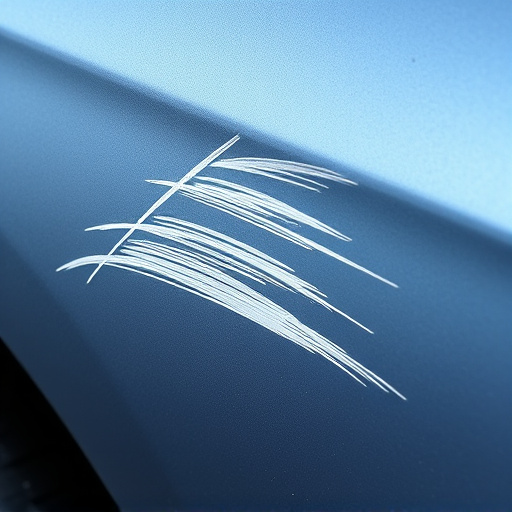

Understanding the characteristics of Mercedes Boron steel is crucial when it comes to precision cutting applications. The alloy’s ability to maintain its integrity during the cutting process ensures that even intricate designs can be realized without compromising structural integrity. This makes it an ideal choice for not just straight-line cuts but also complex patterns, often seen in fender benders or other car damage scenarios, allowing for more effective and efficient repairs, restoring vehicles to their original condition with minimal trace of previous car damage repair efforts.

Cutting Techniques for Minimal Distortion

Cutting Mercedes boron steel requires specialized techniques to achieve precision and minimize distortion. The key lies in using advanced cutting tools designed for this specific metal type. High-quality plasma cutters, for instance, offer precise control over the cutting process, allowing for clean, straight cuts with minimal heat input. This technique is particularly crucial when performing vehicle paint repair or car body restoration, as it ensures that the structural integrity of the steel is maintained while achieving the desired aesthetic results.

Additionally, proper cutting techniques involve strategic material preparation and support. This includes marking and masking to guide the cut accurately and protecting adjacent areas from heat damage. For auto repair services focusing on Mercedes boron steel, these meticulous pre-cutting steps are essential to prevent unwanted distortion that could compromise the overall quality of repairs, be it for vehicle paint repair or intricate car body restoration work.

Advantages and Applications in Industry

The use of Mercedes boron steel cutting offers numerous advantages in industrial applications, setting a new standard for precision and durability. This advanced material is renowned for its exceptional strength-to-weight ratio, making it a game-changer in sectors demanding robust yet lightweight components. Its superior resistance to corrosion and wear ensures that equipment and machinery perform optimally over extended periods, reducing downtime in industries such as automotive manufacturing, collision repair centers, and car bodywork shops—a significant benefit for auto repair near me businesses striving to offer efficient services.

This innovative steel cutting process finds its place in various industries, from construction to aerospace. In the car bodywork sector, it facilitates precise panel fitting and seamless repairs, ensuring vehicles regain their structural integrity without compromising aesthetics. Moreover, boron steel’s ability to withstand extreme temperatures makes it ideal for high-performance applications, contributing to more efficient and reliable machinery.

Mercedes Boron steel cutting, with its exceptional properties and precise techniques, offers a game-changing approach to industrial fabrication. By understanding the unique characteristics of this steel and employing specialized cutting methods, manufacturers can achieve remarkable results with minimal distortion. The advantages are clear: enhanced material strength, improved durability, and a reduced risk of damage during the cutting process. These benefits make Mercedes Boron steel a reliable choice for various industries, from automotive manufacturing to construction, revolutionizing the way we approach metal fabrication.