Tesla repair scanning leverages advanced technology to enhance auto repairs, ensuring high quality and reliability for Tesla owners. By using specialized equipment and algorithms, it offers precise inspections of electrical systems, sensors, and control modules, preventing system failures and saving owners from unexpected breakdowns. This proactive approach prioritizes component evaluation, maintains peak vehicle condition, and sets Tesla maintenance apart from industry standards.

Tesla vehicles are renowned for their cutting-edge technology, but even advanced systems can fail. Enter Tesla repair scanning—a game-changer in predictive maintenance. This innovative process uses sophisticated tools to detect and prevent potential issues before they disrupt your drive. By analyzing sensor data and system performance, it identifies weak signals that might indicate impending failures. Through this proactive approach, owners can avoid costly repairs and ensure their electric vehicles remain reliable for years to come, ultimately enhancing the overall driving experience.

- Understanding Tesla Repair Scanning Technology

- Benefits of Preemptive System Failure Prevention

- Best Practices for Effective Tesla Repair Scanning

Understanding Tesla Repair Scanning Technology

Tesla repair scanning technology has evolved to become a cornerstone in ensuring high-quality car repairs and preventing system failures. This advanced process involves using specialized equipment to thoroughly inspect and diagnose any issues within a Tesla vehicle’s intricate systems. By employing sophisticated algorithms and data analysis, scanning tools can detect even the subtlest anomalies that might go unnoticed during manual checks.

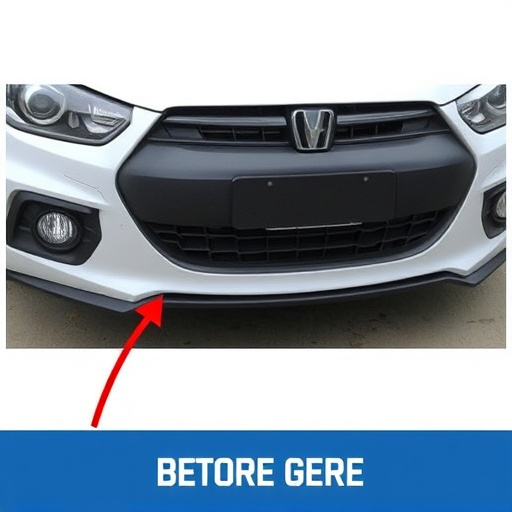

The technology facilitates comprehensive assessments of critical components, such as electrical systems, sensors, and control modules. This includes evaluating frame straightening and car body repair work to maintain optimal vehicle performance. Reputable car repair services leverage these scans to identify potential problems before they escalate, thus enhancing safety and reliability. Tesla repair scanning is a game-changer in the industry, enabling mechanics to stay ahead of system failures and provide owners with peace of mind on the road.

Benefits of Preemptive System Failure Prevention

The benefits of preemptive system failure prevention in Teslas, or any luxury vehicle for that matter, are numerous. By utilizing advanced Tesla repair scanning techniques, mechanics can identify potential issues before they escalate into costly and time-consuming repairs. This proactive approach not only saves owners from unexpected breakdowns but also enhances the overall reliability and longevity of their vehicles.

Preemptive maintenance ensures that minor glitches or warning signs don’t go unnoticed. Through comprehensive scanning, technicians can pinpoint exact problem areas in the electrical system, transmission, or other complex components unique to electric vehicles. This enables targeted repairs, often as simple as software updates or replacement parts, preventing major system failures and what could be expensive vehicle restoration processes. As a result, owners enjoy a smoother driving experience, knowing their Tesla is in peak condition.

Best Practices for Effective Tesla Repair Scanning

When it comes to Tesla repair scanning, implementing best practices is key to preventing repeat system failures and ensuring top-notch vehicle repairs. The process should begin with a thorough initial inspection, utilizing advanced diagnostic tools capable of identifying even subtle issues that might go unnoticed by the untrained eye. Technicians should take their time to review all sensor data, vehicle logs, and error codes, cross-referencing this information against known Tesla repair manuals and databases for accurate diagnoses.

Effective scanning also involves a systematic approach to repairs, where each component is meticulously evaluated before replacement or fixing. This includes checking for proper functionality, wear and tear, and potential compatibility issues with other systems. Additionally, keeping detailed records of the entire process, from initial scan to final test drive, facilitates future reference and ensures that any recurring problems are swiftly addressed. For those looking to maintain their Tesla’s optimal performance, regular scanning coupled with these best practices is a game-changer, even when compared to standards in mercedes benz repair or other auto painting services.

Tesla repair scanning technology plays a pivotal role in preventing repeat system failures, ensuring electric vehicle owners enjoy reliable performance. By proactively identifying and addressing issues, this method offers numerous benefits, including enhanced safety, cost savings, and improved customer satisfaction. Implementing best practices for effective Tesla repair scanning enables service centers to stay ahead of potential problems, ultimately fostering a smoother and more efficient repair process. Embrace this innovative approach to maintain the cutting-edge status of Tesla vehicles and set new standards in the automotive industry.