Computer-aided repair design (CARD) leverages 3D modeling to transform vehicle body repair, enhancing precision and visualization during planning. Technicians create digital replicas, enabling virtual inspections, accurate part fitment, cost estimation, and streamlined operations. This technology benefits complex jobs like frame straightening and routine car scratch repair, offering superior restoration outcomes through detailed digital planning.

In the realm of precision engineering, Computer-Aided Repair Design (CARD) is transforming how we approach complex repairs. This article delves into the profound impact of 3D modeling on enhancing repair design and planning. By understanding the power of this technology, streamlining processes, and visualizing solutions in a three-dimensional space, engineers can optimize outcomes. We explore how 3D modeling facilitates more effective decision-making, reduces errors, and accelerates project timelines, revolutionizing the way we tackle challenging repairs.

- Understanding the Power of 3D Modeling

- Streamlining Repair Design Processes

- Visualizing and Optimizing Solutions

Understanding the Power of 3D Modeling

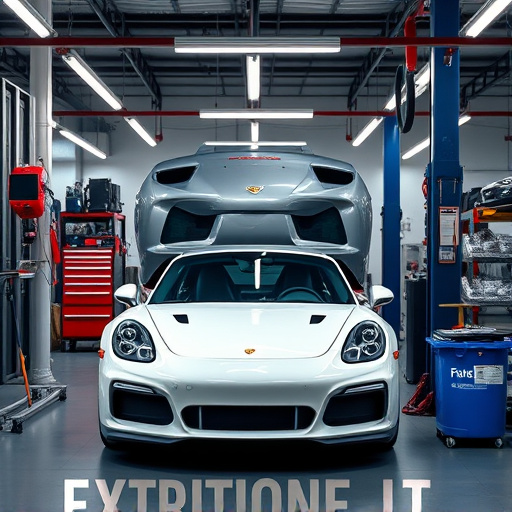

In the realm of vehicle body repair, computer-aided repair design (CARD) is transforming the way we approach and execute repairs. By transitioning from traditional 2D drawings to immersive 3D modeling, car paint services and vehicle body shops are experiencing a game-changer. This innovative technology offers an unparalleled level of precision and visualization, revolutionizing the planning phase for complex repairs.

With 3D modeling, technicians can create detailed digital replicas of damaged vehicles, allowing them to virtually inspect every crack, dent, and scratch. Such a comprehensive view enables more accurate assessments, ensures better fitment of replacement parts, and reduces errors during actual vehicle body repair processes. Moreover, it aids in cost estimation, as the digital model provides an exact representation of what needs to be replaced, thereby streamlining operations for any vehicle body shop.

Streamlining Repair Design Processes

In today’s digital era, computer-aided repair design has revolutionized the way we approach vehicle repair, particularly in tasks like car scratch repair and frame straightening. By utilizing 3D modeling software, technicians can create precise digital replicas of vehicles, allowing for more efficient planning and execution during the repair process. This technology streamlines repair design processes by providing a comprehensive, visual understanding of the vehicle’s structure, enabling professionals to identify potential issues early on and devise effective solutions.

With 3D models, mechanics can virtually manipulate and analyze damaged components, ensuring accurate measurements and fitment before actual work begins. This reduces the likelihood of errors and rework, ultimately saving time and resources in the long run. The process is not just beneficial for complex frame straightening jobs but also simplifies routine car scratch repair, offering a more structured and precise approach to restore vehicles to their original condition.

Visualizing and Optimizing Solutions

In the realm of computer-aided repair design, 3D modeling is a game changer. It allows for the visualization and optimization of solutions in ways that traditional 2D methods cannot match. By creating digital replicas of vehicles, collision repair centers can meticulously plan every step of a vehicle restoration project. This technology enables them to identify potential issues before they arise, ensuring a smoother and more efficient repair process.

The benefits extend beyond mere planning; 3D modeling also enhances the overall quality of body shop services. It facilitates precise measurements and accurate representations of damage, enabling technicians to work with confidence and precision. Whether it’s a complex panel replacement or intricate paint correction, this digital approach ensures that every detail is accounted for, ultimately leading to superior vehicle restoration outcomes.

3D modeling has revolutionized the way we approach computer-aided repair design, offering a robust toolset for enhancing efficiency and accuracy throughout the planning phase. By providing detailed, immersive visualizations, this technology allows for better decision-making, cost reduction, and faster project turnaround times. As we continue to advance in digital capabilities, embracing 3D modeling is essential for staying competitive and delivering high-quality repairs.