3D car scanning technology captures detailed dimensional data using specialized sensors and cameras, creating precise digital representations of vehicles. This enables the detection of subtle body variations like dents, cracks, and misalignments, facilitating accurate analysis for automotive repair and quality control. By mapping every curve and contour, technicians can make informed decisions, ensuring structural integrity and preserving vehicle value.

“Unleashing the power of 3D car scanning technology, this article delves into its ability to detect structural variations with unprecedented precision. By capturing detailed dimensional data, these innovative systems form a robust foundation for accurate detection. Through comparative scans, even subtle differences are unveiled, enabling advanced analysis that interprets variations for meticulous quality control. Discover how this technology revolutionizes the automotive industry, ensuring superior craftsmanship and safety.”

- Capturing Dimensional Data: The Foundation of Detection

- Comparing Scans: Unveiling Subtle Differences

- Advanced Analysis: Interpreting Variations for Quality Control

Capturing Dimensional Data: The Foundation of Detection

The foundation of effective 3D car scanning technology lies in its ability to capture comprehensive dimensional data. This advanced process involves using specialized sensors and cameras to create precise, digital representations of vehicles, focusing on their structural elements. By collecting detailed measurements, the technology can detect even the subtlest variations in a car’s body—a crucial aspect for automotive repair and vehicle bodywork assessments.

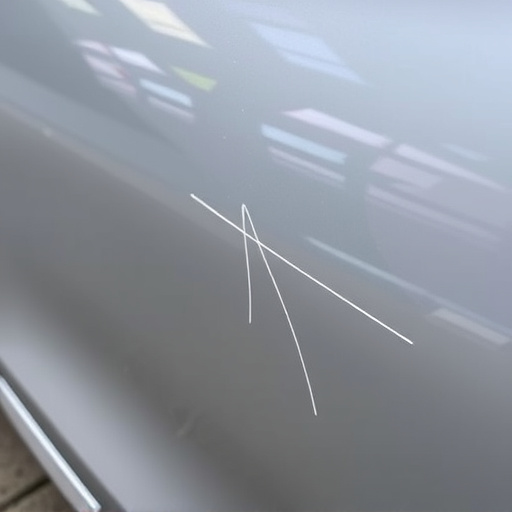

Whether it’s identifying dents, cracks, or misalignments, 3D scanning provides an accurate and efficient method to analyze auto body repairs. The captured data allows professionals to thoroughly inspect every curve and contour, ensuring that structural integrity is maintained across the entire vehicle. This level of precision is invaluable in the automotive industry, enabling faster and more informed decisions for both repair processes and quality control.

Comparing Scans: Unveiling Subtle Differences

When using 3D car scanning technology, the real magic happens when comparing scans to unveil subtle differences in a vehicle’s structure. This advanced process involves meticulously mapping and analyzing every curve, contour, and component of the car body, allowing for an incredibly detailed examination. By creating digital twins of vehicles, technicians can easily detect even the tiniest variances that might be invisible to the naked eye.

These variations could indicate issues such as hail damage repair necessities, subtle deformities from accidents, or differences in manufacturer tolerances. The technology’s precision enables accurate identification and measurement of these discrepancies, making it an indispensable tool for car body repair professionals. Whether assessing the extent of hail damage repair or ensuring a vehicle is in optimal condition, 3D scanning provides irrefutable data for informed decision-making during the restoration process.

Advanced Analysis: Interpreting Variations for Quality Control

The advanced analysis capabilities of 3D car scanning technology go beyond simple visualization. By interpreting variations in a vehicle’s structure, this innovative tool becomes an indispensable asset for quality control in both collision repair and autobody repairs. Scanners capture intricate details, allowing experts to detect even the subtlest deviations from the original design. This precision enables mechanics to identify potential issues or misalignments that might go unnoticed through traditional methods.

With 3D scanning, auto repair services can streamline their processes, ensuring every repair is accurate and of the highest quality. By understanding and documenting structural variations, technicians can make informed decisions, choose the right parts, and perform meticulous repairs, ultimately preserving the integrity and value of vehicles.

3D car scanning technology has revolutionized quality control by providing an unprecedented level of detail. Through capturing dimensional data, comparing scans, and performing advanced analysis, manufacturers can detect even subtle structural variations in vehicles. This innovative approach ensures higher precision, improves manufacturing processes, and ultimately leads to better vehicle performance and safety. By leveraging 3D scanning technology, the automotive industry is poised for continued advancement, enhancing both quality and efficiency.