Technicians in industries like automotive, construction, and manufacturing face slip, trip, and fall risks due to slippery surfaces, loose debris, and uneven terrain. Essential technician safety equipment includes anti-slip footwear, high-visibility clothing, fall protection gear, protective gloves, eyewear, vests, knee pads, and back support belts. Regular cleaning, inspections, proper usage training, and refresher courses are vital for maintaining this equipment and preventing accidents, especially in vehicle repair and restoration.

Technician safety equipment plays a pivotal role in preventing slip, trip, and fall accidents, an often overlooked yet significant hazard in the tech industry. These incidents lead to injuries and downtime, impacting productivity and worker morale. Understanding the risks specific to technicians is crucial. This article explores essential components of safety gear, best practices for maintenance and usage, empowering professionals to safeguard themselves and enhance workplace safety through the strategic implementation of technician safety equipment.

- Understanding Slip, Trip, Fall Risks for Technicians

- Essential Components of Technician Safety Equipment

- Best Practices for Maintaining and Using Safety Gear

Understanding Slip, Trip, Fall Risks for Technicians

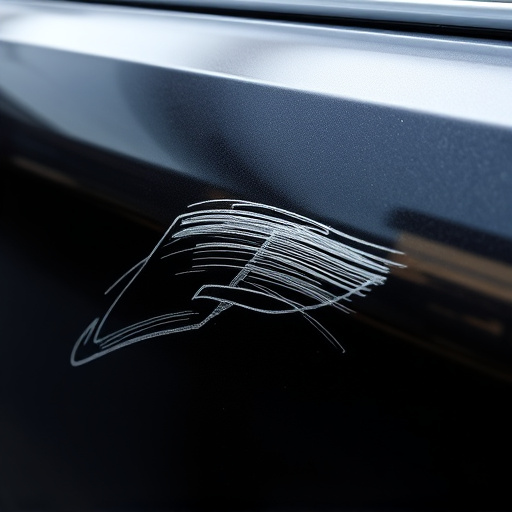

Technicians working in various industries, such as automotive, construction, or manufacturing, face unique challenges when it comes to slip, trip, and fall accidents. These incidents can lead to severe injuries, including sprains, fractures, and head trauma. Understanding the risks involved is the first step towards prevention. Technicians often work in environments with slippery surfaces, loose debris, or uneven terrain, increasing the likelihood of slips and trips. For instance, a paintless dent repair technician might be working on a car’s delicate surface, requiring precise movements to avoid accidental falls or damage to both the vehicle and themselves.

Car body repair and paint services often involve heavy machinery and hazardous materials, adding another layer of complexity. Technicians may need to navigate through cluttered workshops or tight spaces, where trip hazards are prevalent. Proper technician safety equipment, including anti-slip footwear, high-visibility clothing, and fall protection gear, is essential in mitigating these risks. By equipping themselves with the right tools and knowledge, technicians can ensure their well-being and reduce the potential for slip, trip, and fall accidents during their daily tasks.

Essential Components of Technician Safety Equipment

Technician safety equipment plays a pivotal role in preventing slip, trip, and fall accidents, which are common hazards in vehicle repair, automotive collision repair, and even automotive restoration environments. Essential components include sturdy footwear designed to offer traction on slippery surfaces and absorb impact, as well as durable gloves that provide grip and protect hands from sharp edges and debris.

Protective eyewear is another critical element, shielding technicians from flying objects, sparks, and dust particles. High-visibility vests are also crucial for ensuring maximum visibility and safety, especially in low-light or confined spaces. Additionally, proper body positioning aids, such as knee pads and back support belts, help reduce the risk of musculoskeletal injuries during prolonged work sessions, further enhancing overall technician safety equipment effectiveness.

Best Practices for Maintaining and Using Safety Gear

Maintaining technician safety equipment is paramount to ensuring its effectiveness during slip, trip, and fall prevention. Regular cleaning and inspections are best practices that should never be overlooked. This involves checking for any signs of wear, tear, or damage, especially in high-risk areas like grippers, handles, and straps. All defects should be promptly reported and repaired to maintain optimal performance. Additionally, keeping the equipment organized and stored properly when not in use reduces the risk of accidents caused by tripping over loose gear.

Proper usage is another critical aspect of technician safety equipment. Ensuring that every team member is trained on how to correctly put on and take off the gear, as well as its intended function during various tasks, is essential. For instance, using non-slip shoes with appropriate heel heights and grippers when working in automotive body shops or providing car paint services can significantly reduce the risk of slips and falls. Regular refresher courses and reminders about safety protocols help maintain a culture of safety awareness among technicians, ultimately contributing to a safer work environment in any trade that involves tasks like car dent repair.

Technician safety equipment is not just a recommendation; it’s an essential tool in preventing slip, trip, and fall accidents. By understanding the risks unique to technicians, selecting the right gear, and practicing safe maintenance and usage protocols, professionals can dramatically reduce these hazardous incidents. Investing in quality technician safety equipment and adhering to best practices is crucial for fostering a safer work environment and empowering technicians to perform their jobs with confidence and peace of mind.