Before repairing a flexible bumper, assess damage like cracks or dents and gather specialized tools and matching paint. Prepare the surface by cleaning, inspecting for remaining issues, and gently sanding. Engage professional auto maintenance services for optimal outcomes. Apply putty precisely with light pressure and blend layers for an impeccable finish.

“Achieving a flawless finish in flexible bumper repair is within reach with the right approach. Before beginning, assess the damage carefully, ensuring you have all necessary materials at hand. Preparation is key; properly clean and prepare the damaged area for optimal adhesion.

Once ready, apply putty with precision, smoothing it seamlessly to match the vehicle’s curve. This step-by-step guide will walk you through the process, guaranteeing a professional-looking, long-lasting flexible bumper repair.”

- Assess Damage and Gather Materials

- Prepare Surface for Repair

- Apply and Smooth Putty for Perfect Finish

Assess Damage and Gather Materials

Before diving into the repair process, it’s crucial to thoroughly assess the damage on your flexible bumper. Inspect for cracks, dents, or any signs of deformation. This step is essential as it determines the extent of autobody repairs needed and ensures a successful outcome. If there are significant structural issues, consulting an automotive collision repair expert might be beneficial.

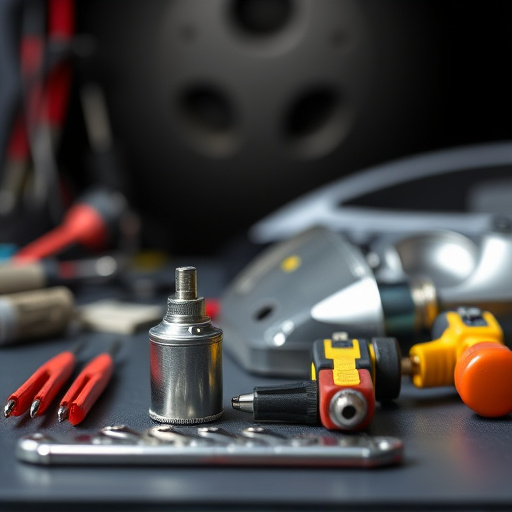

Gather all the necessary materials to conduct the repair efficiently. For a paintless dent repair approach, consider using specialized tools like puffers, hammers, and suction cups designed for removing dents without painting. Additionally, stock up on matching bumper paint or a touch-up kit to match the original color precisely, ensuring no visible repairs once finished.

Prepare Surface for Repair

Before initiating any flexible bumper repair, preparing the surface is a pivotal step. This involves thoroughly cleaning the damaged area to remove dirt, grease, and any loose debris. A clean surface ensures better adhesion for the repair materials, ultimately enhancing the longevity of the repair job. Utilize automotive-grade cleaners and degreasers suitable for plastic surfaces to achieve optimal results. Once cleaned, inspect the bumper for any remaining cracks or dents that might need addressing.

Smoothness is key during the preparation phase. Sanding the surface gently with fine-grit sandpaper can help even out minor imperfections, creating a seamless base for the repair process. This step is especially crucial when dealing with flexible bumpers as proper surface preparation directly impacts the final aesthetics and durability of the vehicle’s appearance. For optimal outcomes, consider engaging professional auto maintenance services that specialize in car paint and bumper repairs.

Apply and Smooth Putty for Perfect Finish

After preparing the damaged area on the flexible bumper, it’s time to apply the putty. Start by spreading a thin layer using a smooth blade or spatula, ensuring complete coverage over the repair site. This initial coating sets the foundation for a perfect finish, filling in any imperfections and creating an even surface.

As you add subsequent layers, take care to blend each one seamlessly with the previous one, using light pressure and gentle strokes to ensure the putty flows smoothly. The goal is to achieve a consistent texture that mirrors the surrounding car body restoration. With patient application and careful smoothing, you’ll be left with an impeccable finish, ready for the final steps in any reputable automotive repair service.

Ensuring a seamless finish in flexible bumper repair requires careful preparation and precise execution. By thoroughly assessing the damage, properly preparing the surface, and expertly applying putty, you can achieve a flawless result that restores your vehicle’s aesthetic appeal. Remember, using high-quality materials and following each step diligently is key to successful flexible bumper repair, ensuring your vehicle looks as good as new.