Adhesive bonding techniques revolutionize car repair, offering versatile solutions for diverse materials and ensuring strong, long-lasting bonds. Choosing the right adhesive, like epoxy or polyurethane, tailored to material and desired results is critical for structural integrity and aesthetic appeal. Meticulous preparation, including cleaning and precise application with strategic clamping pressure, followed by curing per manufacturer guidelines, guarantees robust bonding for both structural and cosmetic repairs.

Adhesive bonding techniques have emerged as indispensable tools in the realm of panel repair and reinforcement, offering strong, lasting solutions. This comprehensive guide delves into the fundamentals of adhesive bonding, equipping readers with essential knowledge for effective repairs. From understanding bond dynamics to selecting optimal adhesives and mastering application techniques, we provide a step-by-step approach for achieving superior results. Reinforce your panels with confidence using these innovative adhesive bonding methods.

- Understanding Adhesive Bonding Fundamentals for Repairs

- Choosing the Right Adhesives for Panel Reinforcement

- Step-by-Step Guide to Effective Adhesive Application Techniques

Understanding Adhesive Bonding Fundamentals for Repairs

Adhesive bonding techniques have become indispensable in the realm of car repair services and classic car restoration. This method involves using powerful adhesives to fuse two or more materials together, creating a strong and durable bond. When it comes to reinforcement panel repairs, understanding these fundamentals is key to achieving optimal results.

In collision repair centers, adhesive bonding offers a versatile solution for joining various components such as metal panels, plastic parts, and composite materials. By carefully selecting the right adhesive, professionals can ensure a secure and long-lasting connection, mimicking the integrity of the original manufacturing process. This technique is particularly valuable in repairing or replacing damaged body panels, ensuring the structural integrity and aesthetic appeal of vehicles, be it a classic car or a modern model.

Choosing the Right Adhesives for Panel Reinforcement

When undertaking reinforcement panel repairs, selecting the appropriate adhesive is paramount to ensure structural integrity and long-lasting results. The choice of adhesive should align with the specific material of the panels and the desired outcome. For example, epoxy adhesives are popular in automotive repair services due to their exceptional strength and resistance to corrosion, making them ideal for vehicle body shop applications. Polyurethane adhesives offer flexibility and durability, which can be advantageous when repairing complex panel shapes.

Understanding the properties of different adhesives is crucial. Some adhesives provide better bonding on certain surfaces, while others are more suitable for specific environmental conditions. In automotive repair services, considering factors like temperature resistance, impact strength, and compatibility with auto painting processes is essential. The right adhesive ensures a strong bond that can withstand routine vehicle stress, enhancing the overall longevity of the repair job.

Step-by-Step Guide to Effective Adhesive Application Techniques

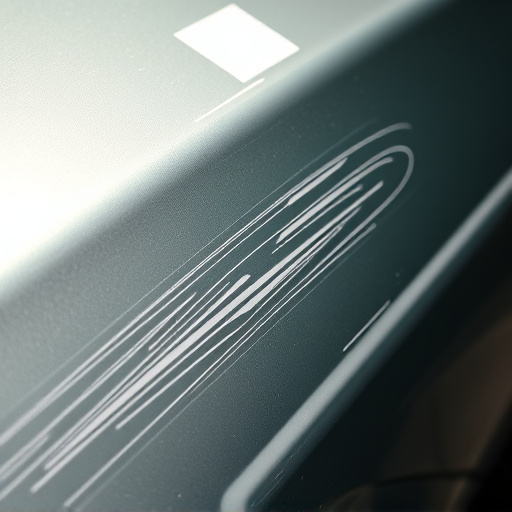

When employing adhesive bonding techniques for reinforcement panel repairs, a meticulous approach is key to achieving strong, lasting bonds. Start by preparing the surface thoroughly; clean it free from grease, dust, or debris using compressed air and ensure rough edges are sanded smooth. This creates a clean canvas for optimal adhesion. Next, choose an appropriate adhesive tailored to your material—whether metal, composite, or plastic—considering factors like temperature, curing time, and resistance to environmental stress.

Apply the adhesive evenly with a precision tool, such as a squeegee or dispenser, ensuring complete coverage without overloading. For complex geometries or challenging contours, use a thin layer and apply pressure strategically with clamping devices to ensure even distribution of the adhesive. Allow the adhesive to cure according to the manufacturer’s instructions before subjecting the panel to stress, making it crucial for auto body repairs or collision repair work. This step-by-step process guarantees robust bonds, ideal for reinforcing panels in both structural and aesthetic applications, like those found in your local auto repair near me.

Adhesive bonding techniques have proven to be a game-changer in reinforcement panel repairs, offering efficient and durable solutions. By understanding the fundamentals, selecting the appropriate adhesives, and mastering application techniques, professionals can ensure robust bonds that enhance structural integrity. This comprehensive approach leverages the power of adhesive bonding to revolutionize repair processes, making it an indispensable toolset for any maintenance or renovation project involving panel reinforcements.